Contactless tool calibration currently under development (ru)

- 5 years ago.

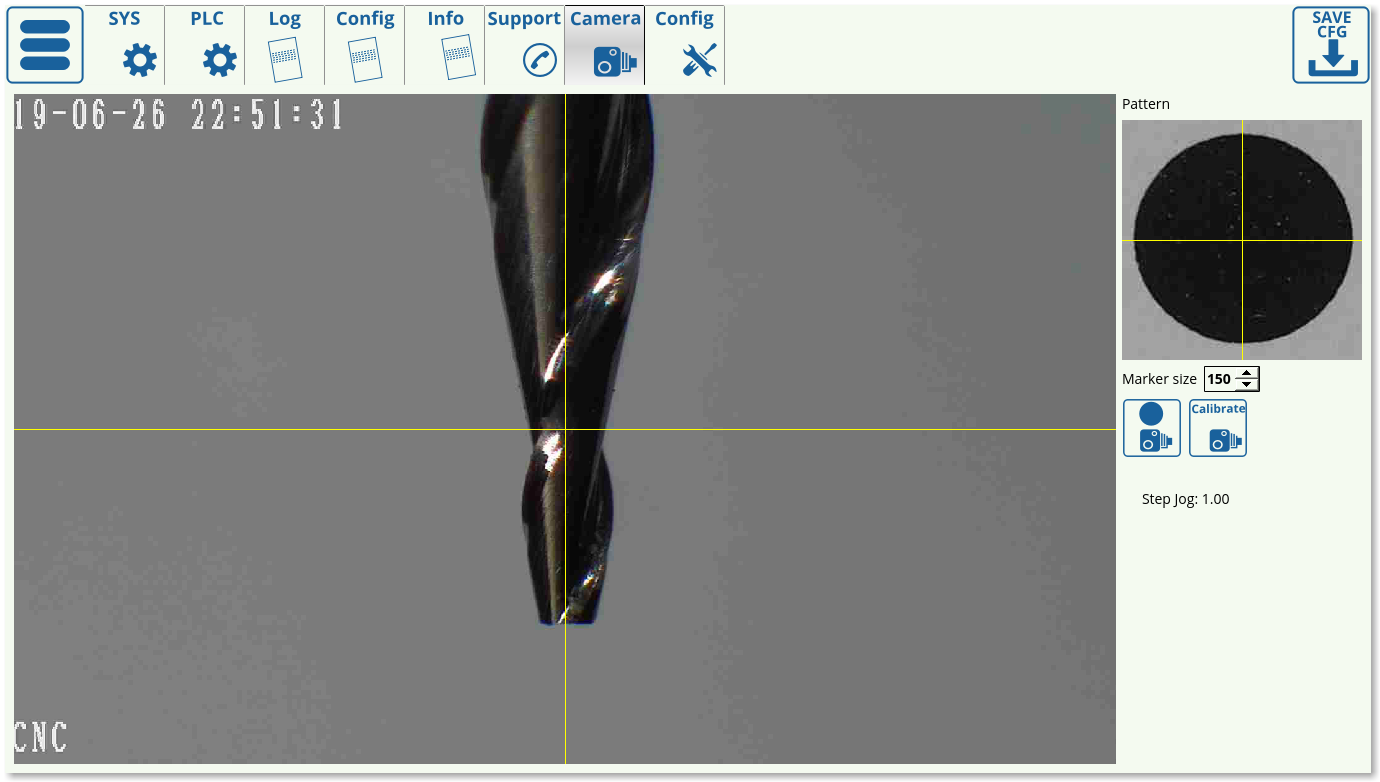

A process for tool calibration using a CNC Vision (camera) setup is currently under development. This procedure aims to calibrate extremely thin spindles (with spindle tip sizes on the order of 0.07-0.1 mm) without having to come into contact with a sensor, which can negatively impact the spindle to the point of breaking due to the sudden impact. Instead, the new calibration process will rely on a fixed camera, the position of which will be known in advance, which would then move the tool until its tip is perfectly aligned with the camera center.

The feature is currently in testing. Stay tuned for further updates.