myCNC 1.88.3789 - Hole cutting speed for plasma, THC improvements (ru)

- 4 years ago.

A new version of myCNC software is now available.

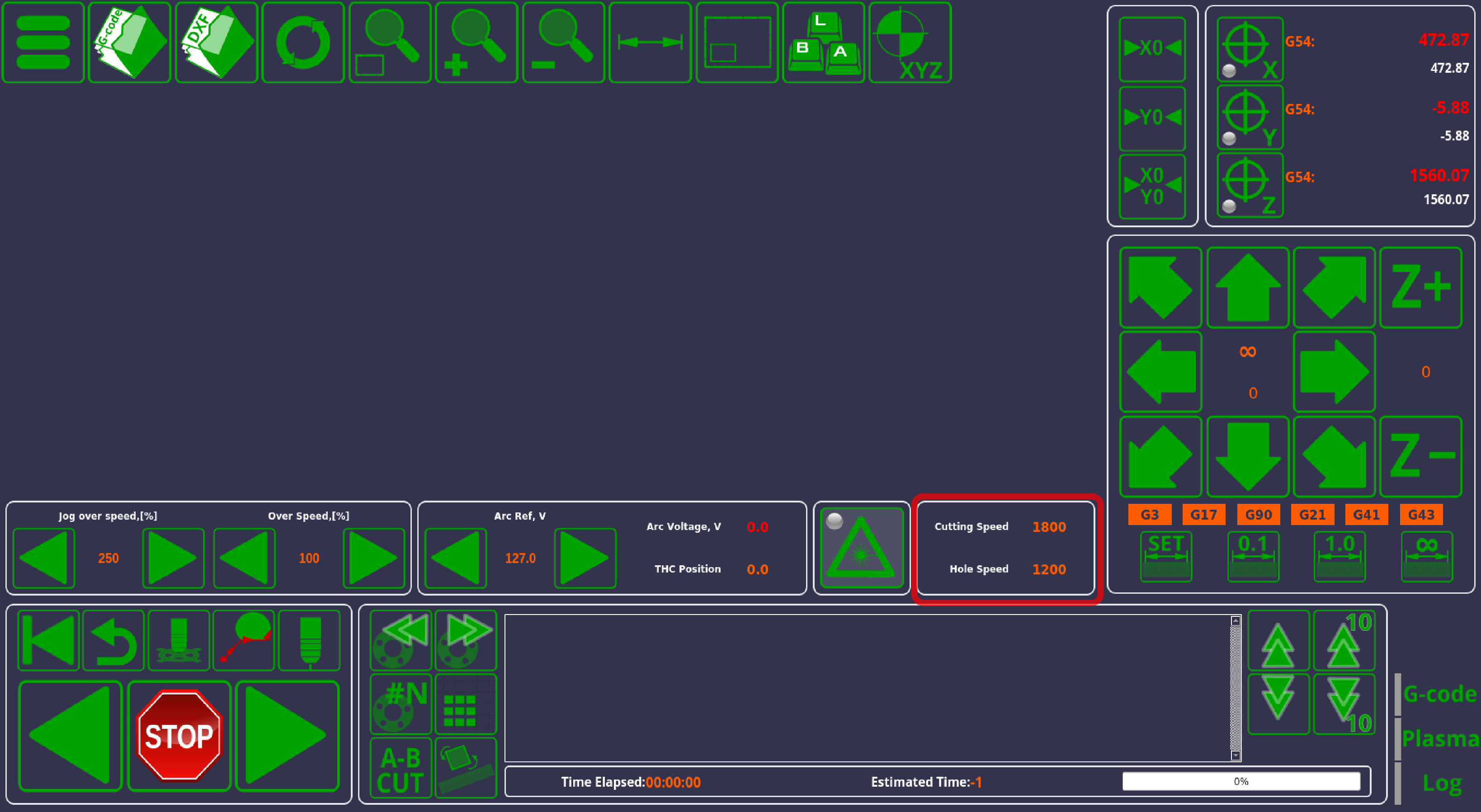

In this version, we have added a separate "Hole Speed" value for hole cutting in plasma profiles. This allows the user to manually set the cutting speeds for holes, or to use the imported cutting speed from the cutcharts (such as the Kjellberg cutcharts, which have a separate category for hole cutting speeds):

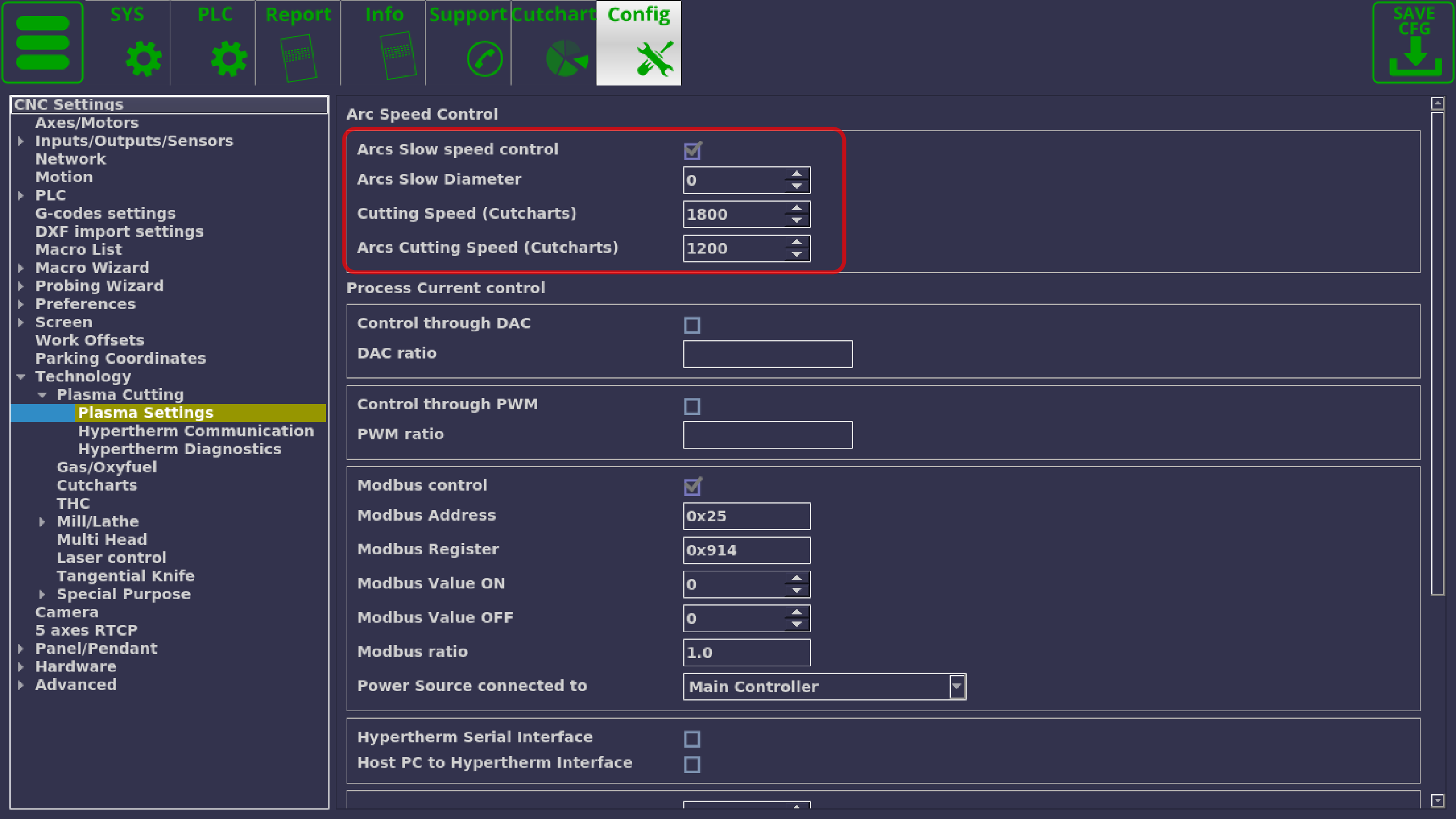

In order to enable this setting, go into Settings> Config> Technology> Plasma Cutting> Plasma Settings, and enable Arcs Slow Speed Control:

The Arcs Slow Diameter allows to set the cutting speed to the hole speed automatically in cases when the diameter of the hole is less than what is specified. If the diameter is set to zero (as in the screenshot above), then only manual switching between the speeds will be available. This is done via the M17/M18 commands to enable/disable hole speed cutting.

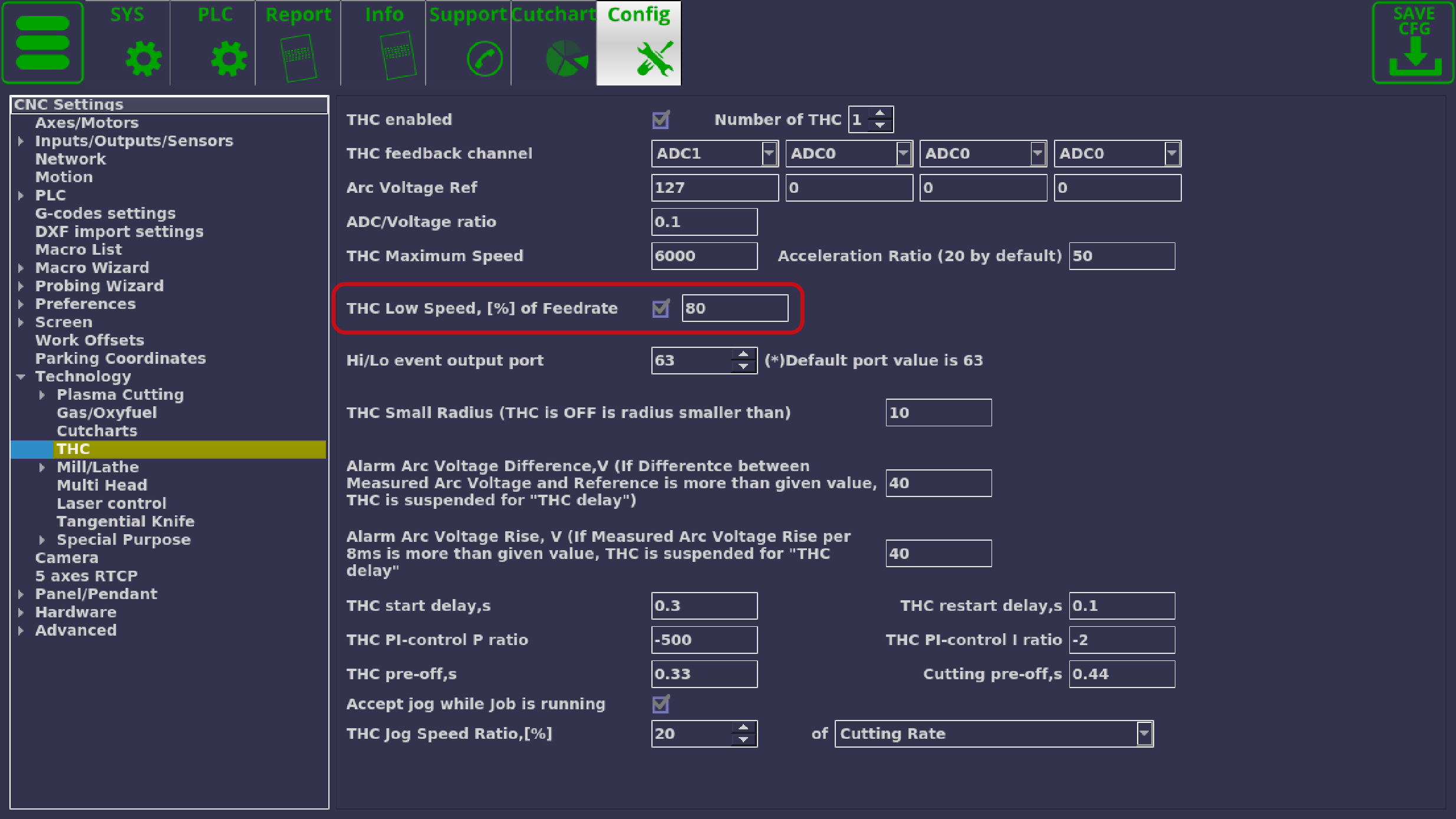

Torch Height Control has been improved by allowing the user to set the percentage of speedrate under which the THC will temporarily turn off (for example, at corners) as opposed to the previous implementation which required the user to input an exact cutting speed below which the THC would be turned off. This is benificial in cases such as the one described above, when multiple cutting speeds are used throughout the cutting job (such as a slower hole speed, etc). The updated THC setting can be found in Settings> Config> Technology> THC> THC Low Speed, [%] of Feedrate:

Note that enabling arc control will disable F-codes present in the G-code program (the hole/arc speed overrides the F-codes). To enable F-codes again, disable arc control.

The updated X1366P profile will be available shortly at our Downloads page.

Stay tuned for more updates!