Minimum Quantity Lubrication (MQL) in myCNC (ru)

- 4 years ago.

myCNC software allows the user to implement MQL, or Minimum Quantity Lubrication, on their machines.

MQL is a process in which tiny drops of high-quality aerosol lubricant are sprayed over the cutting tool and the material, providing lubrication at extremely low rates of lubricant use. This allows for a greatly reduced fluid usage (with the workpiece being nearly dry throughout the lubrication process) as opposed to typical flood setups, resulting in a greener environmental impact and eliminating the need for fluid disposal.

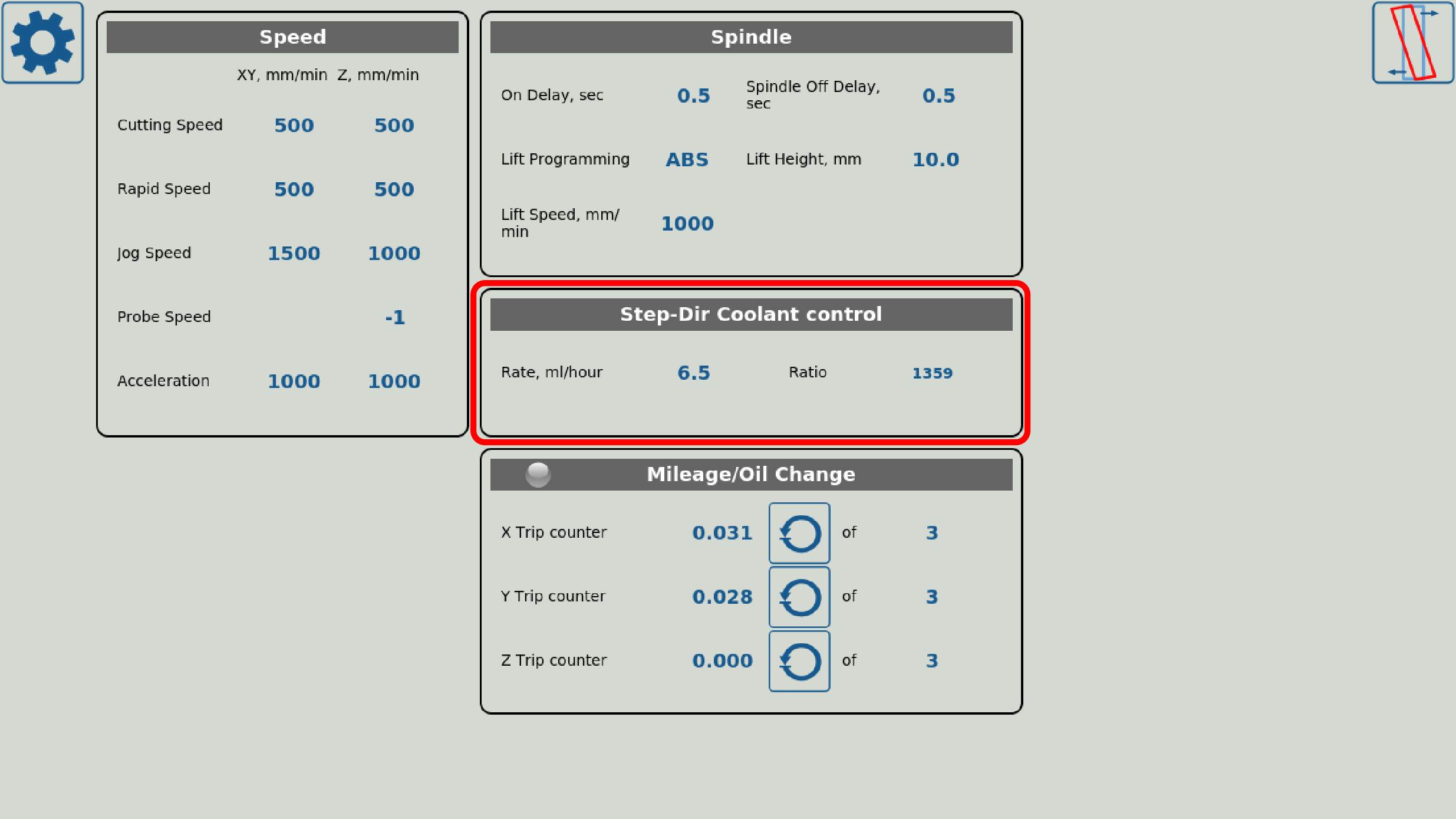

MQL is available in myCNC software by going into the Step/Dir Coolant control tab within User Settings, where you can set the coolant rate:

The fine-tuning is done through the built-in PLC procedures, with the setup described in detail in the Independent Pulse Generator manual. To find out more about Minimum Quantity Lubrication, visit the MQL manual on our Documentation wiki.