Flatbed Correction AutoMeasure

- 7 years ago.

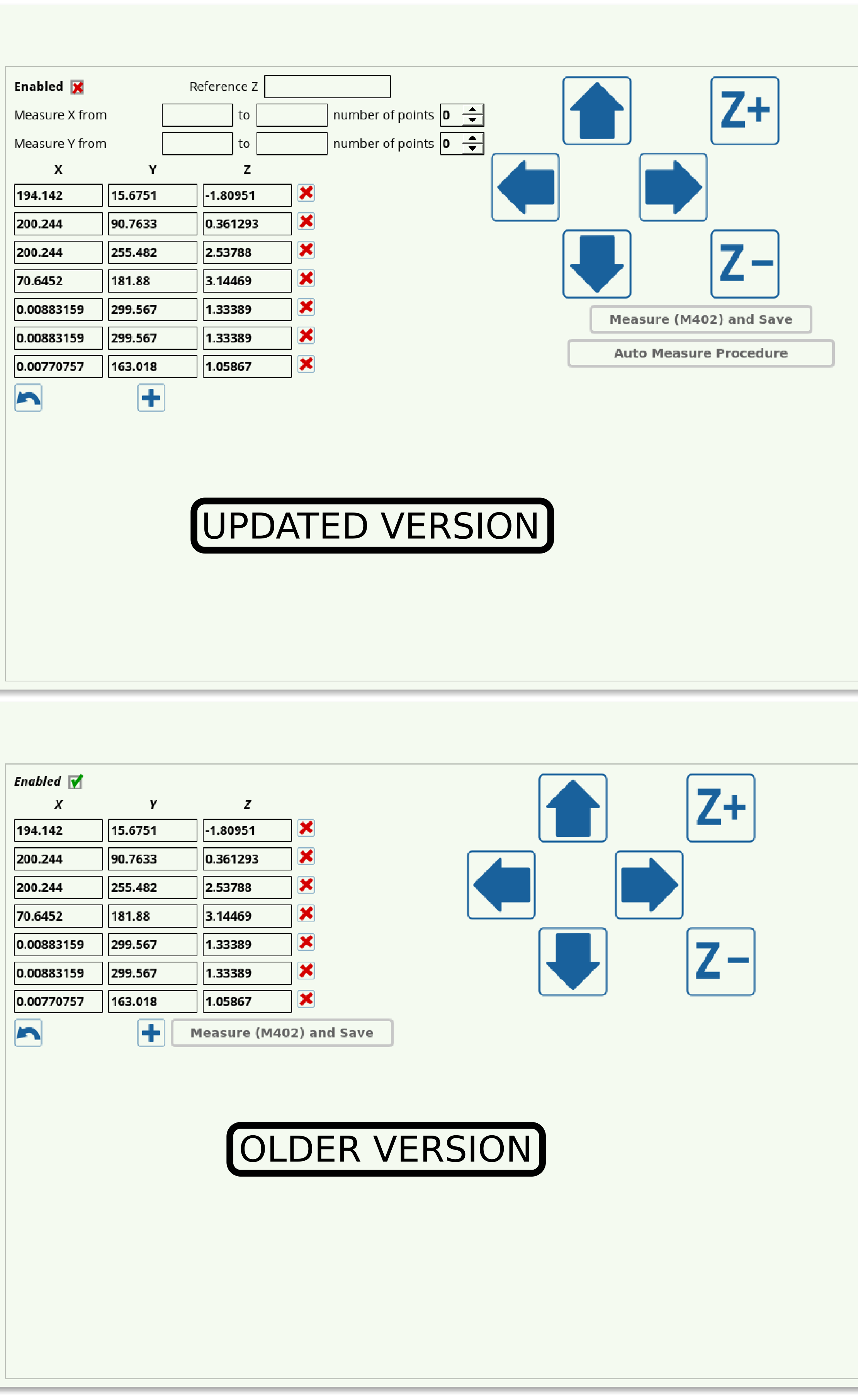

An automatic measurement procedure has been added to flatbed correction in myCNC software. Flatbed correction allows the user to account for the uneven portions of the working surface, by recording the surface z-coordinates over the entire working area or some part of it.

Previously, the process of selecting the points at which the height measurements would be taken was done manually, with the user moving the probe over the surface and lowering it down at each individual point which the software would then record. In the most recent myCNC version, this process has been automated. The user can now set the number of points that the machine must measure, and the coordinates of the area which the machine will be measuring, with the software automatically splitting that area into a number of zones to probe and record the surface height variations.

For more information on Flatbed Correction, please visit its Documentation page.