| Release Date |

Version Number |

Changes / Bug Fixes |

More information |

| Jan 16, 2026 |

2.1.0497 |

- Added functionality for ensuring the system monitors THC Low Speed % correctly during the lead-out phase on plasma cutting applications. Previously, in certain situations the changing F-code would override the THC Low Speed %, causing THC to be on where it shouldn't.

|

|

| Mar 20, 2025 |

2.0.2945 |

- Preliminary/backend update for Bridging functionality in the CAM module (allowing the users to add bridges to inside contours).

|

|

| Mar 12, 2025 |

2.0.2915 |

- Fixed an issue where certain ellipse configurations in DXF files would cause the CAM module to crash

- General stability improvements

|

|

| Dec 04, 2024 |

2.0.2684 |

- Expanded the Motion functionality to allow the user to individually modify and adjust acceleration values for Cut/Rapid/Jog Acceleration.

- Added a number of fixes to improve compatibility for complex/imprecise DXF files in the CAM module. This includes fixes for files with small segments, segments of a zero length, and other files that are now better optimized upon import.

|

|

| Sep 26, 2024 |

2.0.2471 |

- Improvements to the Array window (the Array functionality allows the user to multiply the currently loaded file into a number of columns/rows)

- Fixed a DXF issue where some circles would not properly import into the CAM module

|

|

| Sep 20, 2024 |

2.0.2441 |

- CutStart Marking Mode - this mode allows the user to switch to marking only the pierce points for the loaded file. Press Refresh to switch back to the original cut file.

- Added highlighting for the beginning/end of open contours in the CAM module (green for beginning, red for end) to be able to easily highlight potential file issues.

|

- CutStart mode can be accessed via "action=generate-pierce-array"

|

| Jun 24, 2024 |

2.0.2039 |

- Major additions to dxf2-import (new DXF import functionality)

- Bug fixes and stability improvements

- Fixed a Simulator Displacement Error issue that would sometimes prevent the program from completing

|

|

| Sep 19, 2023 |

1.88.8833 |

- Homing macro wizard - added an inches-millimeters handler to save and restore current program units

- Added the Show Log Popup Messages option in Settings > Screen

|

|

| Jan 16, 2023 |

1.88.5775 |

- Laser cutting improvements

|

|

| Jan 12, 2023 |

1.88.5770 |

- General DXF bugfixes

- Program scrolling bugfixes (next/previous line buttons)

|

|

| Jan 09, 2023 |

1.88.5761

|

- Added a test mode for generating cutting programs with a focus on dental aligner applications

- Given an array of XYZ points, myCNC can generate a program taking into account the rotary axis and the orientation of the workpiece

|

|

| Dec 15, 2022 |

1.88.5741

|

- Worked on the camera marker recognition preprocessor - positioning system to a specified Z-position indicates to the system to initiate the camera commands (M397 etc)

- GUI for the option for global variable 7696 (ignore F-codes) added to Config Settings

|

|

| Nov 29, 2022 |

1.88.5699

|

- New firmware version - Overspeed % now adjustable to 0 (complete stop)

- Pause button - action="player-pause" for pause/start based on this 0% overspeed functionality

- Correct Block support for DXF Import (now accounts for proper rotation for Block DXF elements)

|

|

| Nov 14, 2022 |

1.88.5682

|

- DXF update - dxf2-import functionality

- Geared towards plasma support, allows for precise lead-in and lead-out customization, scaling, proper kerf support

|

|

| Nov 09, 2022 |

1.88.5678

|

- Backend DXF import functionality modifications

|

|

| Oct 28. 2022 |

1.88.5669

|

- DXF/HPGL toolpath generation improvements

|

|

| Oct 21, 2022 |

1.88.5667

|

- Visualization change - highlights program area (2D programs)

- Added player-nc-tie1/2/3/4 functionality to be able to utilize buttons that tie the current working point to a specific corner of the program area

|

|

| Oct 10, 2022 |

1.88.5649

|

- Minor DXF backend changes

|

|

| Sep 16, 2022 |

1.88.5614

|

- Fixes a bug in the kspinbox UI element

- On lathe setups, fixed the G41/G42 compensation codes as well as additional tool compensation

|

|

| Sep 14, 2022 |

1.88.5612

|

- Added the “confirm” and “direct” options for tools specifications window M421 button in order to be able to launch the M421 macro without a confirmation slow speed distance dialog

|

|

| Sep 13, 2022 |

1.88.5609

|

- Added an option to the DXF Import functionality that allows to generate different tools from the DXF file based on colours (as opposed to layers)

|

|

| Sep 09, 2022 |

1.88.5608

|

|

|

| Sep 07, 2022 |

1.88.5606

|

- New commands for Server API (to get filepath, file name, etc)

|

|

| Sep 06, 2022 |

1.88.5604

|

- DXF import update - added a Segment Merge Tolerance option in the Config dialog for DXF Import to prevent issues with visualizations in the import window (previously some lines would not connect on the import visualization screen)

- Fixes to HPGL file import - fixed issue where certain files would crash the myCNC program

|

|

| Sep 02, 2022 |

1.88.5601

|

- Minor DXF import bug fixes

|

|

| Sep 01, 2022 |

1.88.5600

|

- DXF import updates and improvements

- faster DXF loading, improved handling of large files

- Improved spline support

- Tool path optimization improved (now internal contours are cut first, after which external contours for each part are cut)

|

|

| Aug 09, 2022 |

1.88.5565 |

- Added Password Widgets functionality, allowing to create a hidden widget that is opened by entering a passcode

- Optimized large CorelDRAW (.cdr) files that would previously take a long time to open

|

|

| Aug 03, 2022 |

1.88.5555 |

- Fix to correctly distinguish between layers and groups of objects in CorelDRAW (.cdr) files as well as .cdr file spline optimization

|

|

| Jul 29, 2022 |

1.88.5567 |

- Added the time-display GUI element to be able to display global variables such as #6120, etc, in a 00:00:00 format (instead of a less convenient display of a global variable with time in seconds)

|

More info here |

| Jul 28, 2022 |

1.88.5545 |

|

|

| Jul 26, 2022 |

1.88.5498 |

- Modified the ATC pots tool1view element to be able to correctly display the ttime (working time) element (would previously crash the program)

|

|

| Jul 20, 2022 |

1.88.5481 |

- Added new profile actions for the lathe profile (player-simulate-backward and player-simulate-forward)

- Support for controlling an independent axis from a PLC

|

|

| Jul 06, 2022 |

1.88.5463 |

- Bug fixes for G20/inch setups and tracking for an independent axis for plasma and laser

|

|

| Jun 23, 2022 |

1.88.5460 |

- Experimental function - updated the system to allow to load in CorelDraw .cdr files. Currently in alpha stage.

|

|

| Jun 21, 2022 |

1.88.5449 |

- Minor improvements to the inch/mm conversions within the system

|

|

| Jun 02, 2022 |

1.88.5434 |

- Bug fix - fixed an issue with the Tool Length Measure macro wizard where the Fast Move Down line was not added to the generated macro

|

|

| May 31, 2022 |

1.88.5428 |

|

|

| May 26, 2022 |

1.88.5405 |

- Minor under-the-hood changes

|

|

| May 5, 2022 |

1.88.5378 |

- Under-the-hood laser cutting functionality changes

|

|

| May 03, 2022 |

1.88.5377 |

- Experimental feature - added the G130 command that allows the user to select a cutcharts mode from within a G-code program

|

- For example, G130 P217 will select mode #217

|

| Apr 28, 2022 |

1.88.5369 |

- Under-the-hood laser cutting functionality improvements

|

|

| Apr 19, 2022 |

1.88.5355 |

- Added Focus Control to laser settings

- Preliminary fixes for an issue with the ruler functionality causing slowdowns during DXF import

|

|

| Apr 17, 2022 |

1.88.5353 |

- Added ruler/grid to the ncview program visualization screen

|

|

| Apr 08, 2022 |

1.88.5339 |

|

|

| Apr 07, 2022 |

1.88.5333 |

- Bug fix - fixed a DXF import issue when the Plasma option was enabled in the list of available tools

|

|

| Mar 30, 2022 |

1.88.5332 |

- Laser cutting functionality improvements

|

|

| Mar 29, 2022 |

1.88.5330 |

- ktab support added (currently used for laser cutting applications in the Y1366LAS profile)

|

|

| Mar 24, 2022 |

1.88.5325 |

- General laser cutting improvements

|

|

| Mar 11, 2022 |

1.88.5315 |

- Optimizations for large tangential cutting programs featuring arcs subdivided into short linear segments, allowing myCNC to look for lines/arcs on a contour

|

|

| Mar 09, 2022 |

1.88.5300 |

- Bug fixes - potential fix for an issue arising on large G-code programs using CNC Vision

|

|

| Mar 08, 2022 |

1.88.5294 |

|

|

| Feb 24, 2022 |

1.88.5274 |

- Added the Tune Z option as an alternative to Correction Z (the former being designed for mill/lathe machines, while the latter is meant for routers)

|

|

| Feb 22, 2022 |

1.88.5253 |

- Bug fixes - fixed an issue with popup windows,

- Bug fixes - on-the-fly tool length corrections (global variables #4701, etc)

- Fixes to CNC vision G-code transformations via camera markers

|

|

| Feb 15, 2022 |

1.88.5245 |

- Under-the-hood upgrades (not yet available to the end user):

- Changes in preparation for the ktab tabbed window element support, capacitive sensor calibration, and independent laser cutting tracking system

|

|

| Feb 14, 2022 |

1.88.5240 |

- Bug fixes - fixed the pipe cutting visualization issue where the cursor movement would not match the toolpath

|

|

| Feb 07, 2022 |

1.88.5230 |

- Changes to HardPendant (MPG support)

|

|

| Feb 01, 2022 |

1.88.5223 |

- Added the ability to initiate Jog commands from PLCs via the global variables # 8630-8635

- Changed and improved the way speed and acceleration are set for AxisPlus, allowing for reverse movement

- Added an option to choose between keeping the program rotation angle after program reload (previously the default option), or resetting the rotation angle to 0 on reload

|

|

| Jan 24, 2022 |

1.88.5214 |

- Added software support for the updated ET7 and ET10 controller versions

- Polish localization update

- Bug fixes - fixed an issue with G33 threading and tool offsets on lathe cutting setups

|

|

| Jan 18, 2022 |

1.88.5205 |

- Bug fixes for tangential knife cutting

- Fixed an issue with tangential cutting present on circles with a small radius

- Minor Kiss-Knife fixes

|

|

| Jan 13, 2022 |

1.88.5195 |

- Bug fixes - fixed an issue with the indication of actual machine position coordinates when using encoders

|

|

| Jan 07, 2022 |

1.88.5185 |

- Added the functionality for the G10 L200 - G10 L205 commands to myCNC

|

- G10 L200 P_reg1 Q_reg2; reg1 = sin(reg2)

- L201 - cos

- L202 - tan

- L203 - asin

- L204 - acos

- L205 - atan

|

| Dec 16, 2021 |

1.88.5171 |

- DXF import - added the ability to enter different Tool Lift values for different types of tools

|

|

| Dec 02, 2021 |

1.88.5137 |

- Additional visualization fixes

|

|

| Nov 30, 2021 |

1.88.5132 |

- 3D plasma bug fixes

- Changes in the system's 2D visualization rendering

|

|

| Nov 10, 2021 |

1.88.5126 |

- Modifications for the Hypertherm Automatic Gas Console functionality

- Added global variables #7467-7471 for system codes and 7472-7473 for AGC preflow/cutflow testing

|

|

| Oct 18, 2021 |

1.88.5076 |

|

|

| Oct 07, 2021 |

1.88.5059 |

- Added functionality for two new global variables

- GVAR_CUTPROCESS_CREEP_TIME (global variable #7650, which allows to assign creep time in seconds) and GVAR_CUTPROCESS_CREEP_SPEED (global variable #7651 for creep speed)

|

|

| Oct 04, 2021 |

1.88.5038 |

- Improvements to Run From Here procedure and single-block-mode for turning applications

- Speed optimizations for circular interpolation

|

|

| Sep 24, 2021 |

1.88.5005 |

- New global variables for oxyfuel cutting - full list of variables available here

- Bug fix - fixed a bug with the Run from Here functionality selecting an incorrect line on large G-code programs (100K+ lines)

- Bug fix - fixed an issue with arc interpolation

|

|

| Sep 22, 2021 |

1.88.4998 |

|

|

| Sep 20, 2021 |

1.88.4989 |

- Tangential cutting optimization and bugfixes

- Fixed an issue with DXF files generated in programs such as Corel that would feature corners composed of small joints of lines/arcs. Modified the program to recognize and properly process such areas.

|

|

| Sep 13, 2021 |

1.88.4978 |

|

|

| Sep 10, 2021 |

1.88.4972 |

- Added the 64200 and 64201 global variables to the myCNC software

- Writing a widget's ID (specified in the XML files as id="NUMBER") into 64200 brings up the corresponding widget

- Writing a widget's ID into 64201 hides the corresponding widget

- For example, the command G10 L80 P64200 Q100 will show widget with id="100"

|

|

| Sep 02, 2021 |

1.88.4956 |

- Bug fixes for:

- CNC Vision

- V-knife

- Knife 180 functionality

|

|

| Aug 20, 2021 |

1.88.4910 |

- XML Editing - Added the attribute "pressed-delay-xxxx" for the "direct-run:" action

- Allows to define time, in ms, that the on-screen element (button, etc) must be pressed for, in order to initialize the direct-run action

- Fixed a bug that would sometimes cause crashes on large-size G-code files

- Fixed a visualization bug for work position

|

|

| Aug 17, 2021 |

1.88.4895 |

- Numerous bug fixes

- Fixed arc handling for DXF files and G21 files on G20 profiles

- Fixed DXF import bug where G21 would be added to the start of the generated program regardless of profile unit settings

- Fixed rotation widget issue on G20 (U-series) profiles

- Fixed M71 Imperial parts library for G20 (U-series) profiles

- Fixed work offsets config tab issue where G58/G59 values would be overwritten upon saving

- Fixed parking config tab visual bug where axes YZ would display values equal to X parking coordinate

|

|

| Aug 12, 2021 |

1.88.4869 |

- Bug fixes for inch/G20 setups

- Fixes for Work Offsets, Cut from Edge, program rotation

|

|

| Aug 07, 2021 |

1.88.4855 |

- Added support for the mycnc-ET8 controller

- The ET8 is a direct copy of the ET6 with altered microchip architecture

- Numerous bug fixes to inch/G20 profiles

|

|

| Aug 04, 2021 |

1.88.4820 |

- Changes to the Alarms settings window - added the Software PLC Handler section for each alarm/sensor type

- Allows for easy custom PLC procedures launch upon alarm trigger

- Sensor trigger mirrored to global variables 9300-9363

- New XML GUI element - tool1view

- Indicates information on a particular tool, including Tool ID, Cutting Material, Tip, Tool Diameter, Tool Max/Elapsed Lifetime, etc

- New global variable #8025 - indicates elapsed tool lifetime, in (100% * WorkTime/MaxTime)

|

|

| Aug 02, 2021 |

1.88.4817 |

- Tool Specification widget improvements

|

|

| July 27, 2021 |

1.88.4814 |

- Improvements to the ATC Pots section in Settings > Config

- Added the Tool Tips, Cut Material, Tool Diameter and Tool ID sections

- Minor changes to the Tool Specifications widget

|

|

| July 17, 2021 |

1.88.4803 |

- Bug fixes for inches/G20 setups - tool length value table and measurement macro fixes

|

|

| July 14, 2021 |

1.88.4794 |

- Added a toggle for G20/G21 handler in Config > Macro Wizard > Tool Change for generating the M6 Tool Change macro.

- Allows to use mixed G20/G21 commands within the body of the control program, switching to the default profile units for the duration of the tool change

- Bug fixes

- Fixed the 3D dimension visualization to display the values correctly when inches were selected in Config > Screen

- Fixed the 3D visualization toggle for showing/hiding program dimensions

|

|

| July 2, 2021 |

1.88.4771 |

- Bug fix - fixed issue where the subroutine call wouldn't initialize due to empty lines or comments at the beginning of subroutine

|

|

| June 29, 2021 |

1.88.4766 |

- Tangential cutting fixes

- Fixes for Windows version - fixed certain button icons not displaying properly on some systems

|

|

| June 28, 2021 |

1.88.4757 |

- Tangential cutting bug fixes - fixed issue with program start after stopping

|

|

| June 14, 2021 |

1.88.4731 |

- Bug fixes for step mode

- Bug fixes for the G76 threading cycle

|

|

| June 8, 2021 |

1.88.4719 |

- Added a checking procedure to compare the current tool number versus the tool # according to the program

- Useful in cases where the tool change procedure did not work correctly for any reason

- The checking procedure can be turned off in settings

- Bug fix for checking whether the machine has moved beyond the soft limits

|

|

| May 17, 2021 |

1.88.4710 |

- Bug fixes for inch/G20 software configurations

- Fixed Return to working point button

- Fixed nesting window, rotation window

- Fixed arc/hole speed

- Fixed tool offsets

- Numerous visual fixes

|

|

| May 3, 2021 |

1.88.4685 |

- Soft Limits control improvements - bug fixes for program bounds calculations

- Firmware updated (testing stream): Changed acceleration behaviour when Overspeed values are changed by a large amount (for example, from 10% to 100%)

- Modified behaviour from immediate change to smooth acceleration, preventing an impact to the machine hardware

- Minimum Overspeed adjustment is now 1% (previously 5%)

|

|

| Apr 28, 2021 |

1.88.4677 |

- Additional bug fixes for soft limits (for rotational axes), drilling cycles and step mode

|

|

| Apr 25, 2021 |

1.88.4664 |

- Windows bug fix - fixed missing icons in the probe sensor widget

|

|

| Apr 21, 2021 |

1.88.4648 |

- Tangential control updates for working with multiple tools with different offsets on the rotary axis

|

|

| Apr 19, 2021 |

1.88.4634 |

- Bug fixes for drilling cycles

- Bug fix - fixed issue with program control going beyond soft limits

|

|

| Apr 15, 2021 |

1.88.4609 |

- Modifications to the independent axis (AxisPlus) for grinding functionality

- Bug fix - fixed an issue with single block mode

- Bug fix - fixes to program rotation functionality

- Bug fix - fixed crashing issue when closing multiple pop-up windows

|

|

| Apr 08, 2021 |

1.88.4592 |

- Bug fix - fixed issue with the G84/G74 tapping commands in situations when the spindle encoder was using a gear ratio different from 1:1

|

|

| Apr 02, 2021 |

1.88.4592 |

- Bug fix - fixed flatbed correction not turning off on Windows machines

- Bug fix - fixed soft limits issues for rotational axes

|

|

| Mar 31, 2021 |

1.88.4586 |

- Drilling cycles - support for variable lowering distance, drilling lift speed

- Improvements for tapping cycles G84, G74

- Various bug fixes

|

|

| Mar 12, 2021 |

1.88.4543 |

- Added new setup options for Machine Axis Configuration

|

|

| Mar 7, 2021 |

1.88.4538 |

- DXF import - added pneumatic lift selection for the Pen tool

- Improved algorithms for 5-axis jewelry cutting

|

|

| Mar 4, 2021 |

1.88.4512 |

- AxisPlus support for ET10 and ET15

- Speed priority bug fixes

|

|

| Mar 3, 2021 |

1.88.4507 |

- New options added in the Hard Pendant settings tab

|

|

| Feb 26, 2021 |

1.88.4494 |

- Added a new global variable #7696 - GVAR_CUTCHART_FEEDRATE_PRIORITY

- if set to 0, then the F-code value for speed is used, if present

- if set to 1, then speed from Cutcharts has a higher priority and the F-code is ignored

|

|

| Feb 24, 2021 |

1.88.4480 |

- Added hardware pendant support for the ET15 controller

- Improvements to the G-code parser when setting arcs via radius for certain post processors (fixed the issue where in cases the G-code contained 2 decimal places the rounding for radius value was not done correctly)

|

|

| Feb 19, 2021 |

1.88.4474 |

- Improved handling of the desynchronization FError in myCNC

- Expanded functionality - ability to turn off servos with the ServoOn signal, sending messages and blocking start up in case of errors from Closed-Loop PID regulators

- Added new settings in the Analog Closed Loop tab

|

|

| Feb 16, 2021 |

1.88.4462 |

- Bug fixes for turning/lathe operations - fixed issue with specifying diameter dimensions

- Interface tweaks to accomodate hardware support for ServoOn signals for drivers in closed-loop systems, and the FError parameter

|

|

| Feb 14, 2021 |

1.88.4460 |

- Hardware Pendant capabilities added

|

|

| Jan 27, 2021 |

1.88.4432 |

- Added the ability to launch Software PLC procedures from hotkey commands

|

|

| Sep 11, 2020 |

1.88.4151 |

- 2-axis configurations support for Creasing Wheel and Pen setups when using the DXF import

- Fixed an issue with the DXF import not correctly recognizing the 2-axis configurations at low turning angles

|

|

| Jul 31, 2020 |

1.88.4103 |

- UI toggles for Tool Specifications window added in UI Settings

- Hole Cutting options duplicated from Plasma Settings to Motion

|

|

| March 6, 2020 |

1.88.3815 |

- Bug fixes for subroutines - subroutine visualization now works correctly on 3D visualizations (M- and V- series profiles).

|

|

| Feb 25, 2020 |

1.88.3803 |

- More behind-the-scenes support for cutcharts added

|

|

| Feb 24, 2020 |

1.88.3797 |

- Built-in images for the Kjellberg CutFire100i cutcharts added

|

|

| Feb 13, 2020 |

1.88.3789 |

- Addition of "hole speed" register to reduce speed during hole cutting on plasma profiles

- THC improvements to allow the user to specify the percentage of feedrate below which THC will be temporarily turned off (as opposed to the previous implementation which required to specify the exact speed)

- Behind-the-scenes support for more cutcharts added

- A number of existing cutchart images uploaded in higher resolution / reworked

|

|

| Feb 4, 2020 |

1.88.3782 |

|

|

| Feb 3, 2020 |

1.88.3778 |

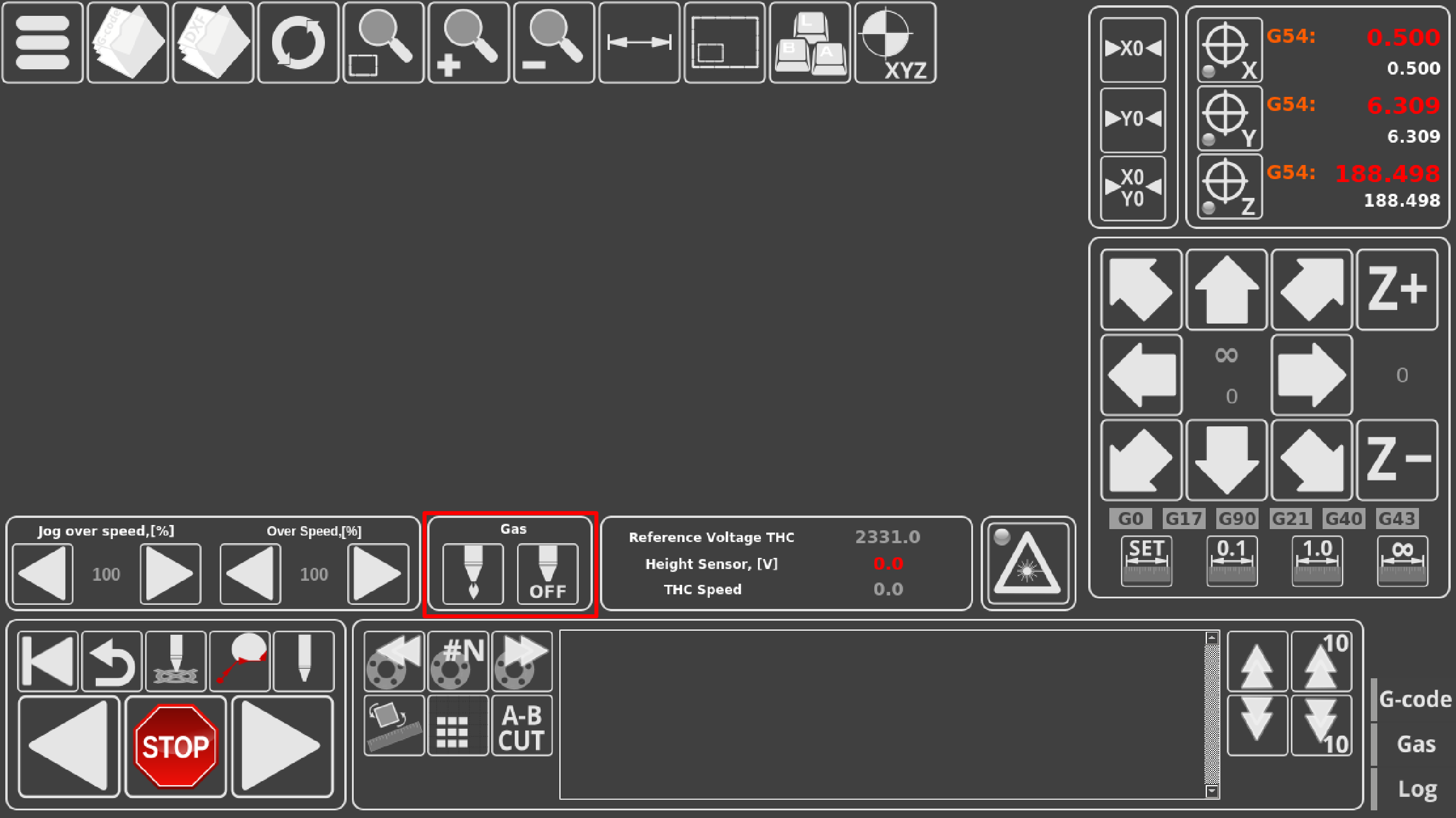

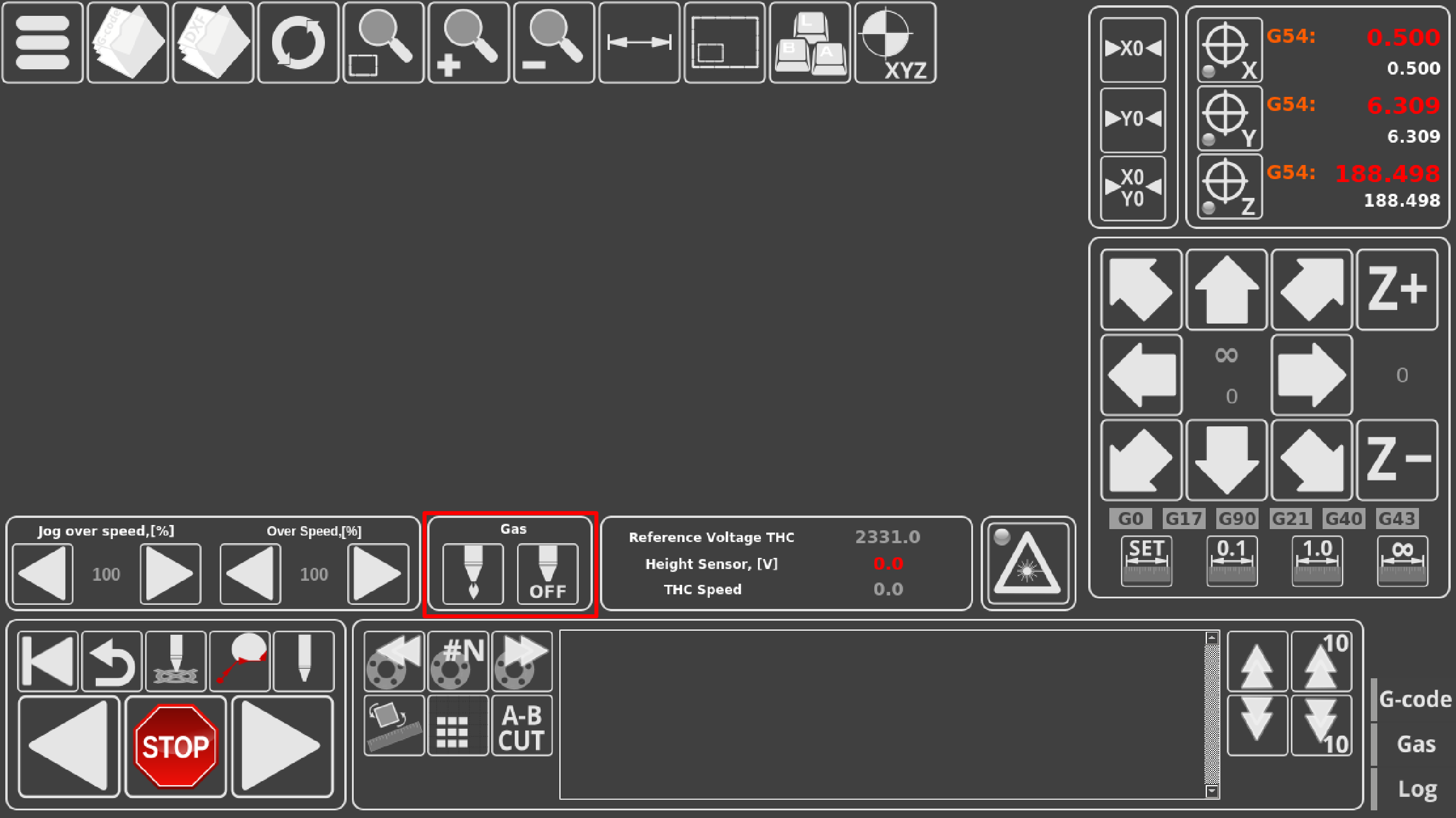

- The X1366G/X1366GA profiles now have the gas on/off button icons added automatically in new profile versions

- General QOL improvements

|

(Click to view)

|

| Jan 29, 2020 |

1.88.3777 |

|

|

| Jan 23, 2020 |

1.88.3771 |

- Bug fixes to the filtration system (encoder behaviour fixed)

|

|

| Jan 21, 2020 |

1.88.3759 |

- Filtration system for signals from controller inputs and operator panel added

- Report Tab bug fixes: pierce time, tool path length and cutting length are now displayed correctly

- Disabled the clickable consumables link that previously led to this website in the Cutcharts widget on X1366P and X1366G type profiles.

|

|