|

Notice. We've been notified that Google shows this page quite often and we need to add this explanation. Our new control boards myCNC-ET7, myCNC-ET10 already include Built-in THC control for Plasma, Gas, Laser cutting AND differential amplifier for ADC input to connect Arc Voltage. That's the reason THC add-on board described in this article is completely obsolete. Please check myCNC-ET7 board, myCNC control software for Plasma if you need CNC control with built-in THC. |

myCNC controllers ET1, ET5 contain ADC inputs that accept 0...5V signal range. It means input analogue signal should be up to 5V relative to COMMON (GND) wire of Ethernet control board (ET1, ET5).

For higher range (for example 0...24V) simple resistor-based voltage divider can be used.

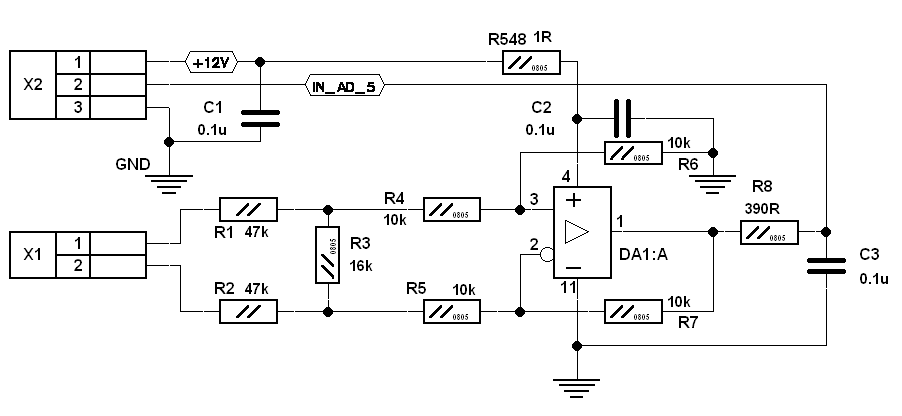

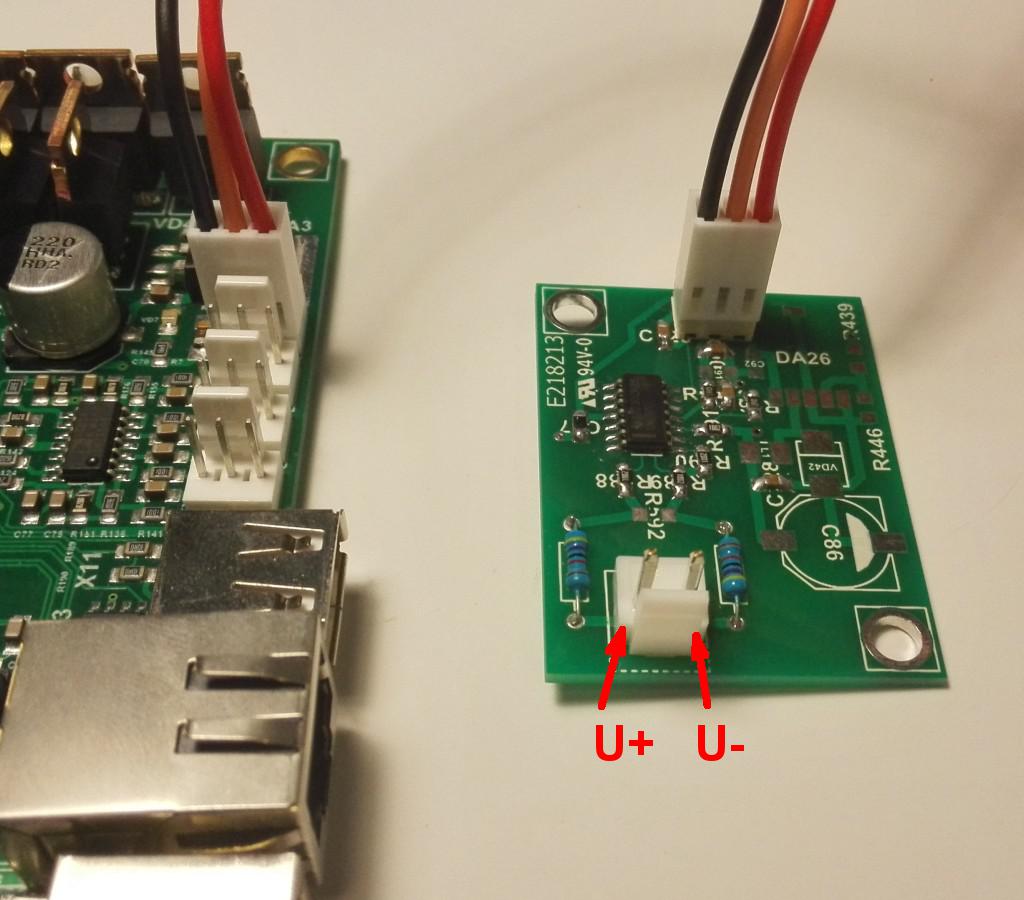

In case of negative analogue signal (for example -15V...0V), dual polarity signal (-15V...15V) or signal not relative to COMMON (for example signal from Plasma power source voltage divider) differential amplifier may be used to convert the signal to 0...5V voltage range.

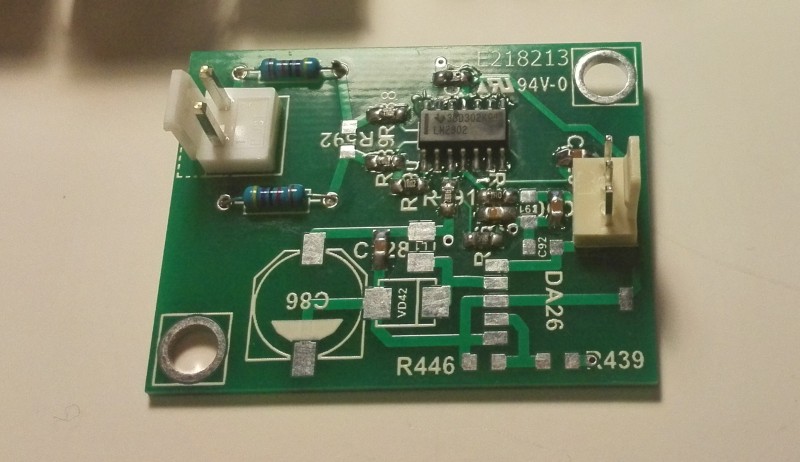

THC addon board is simple differential amplifier with attenuation about 1/5.5. It's suitable to convert signal with up to 30V magnitude to 0...5V range for ET1 or ET5 control board.

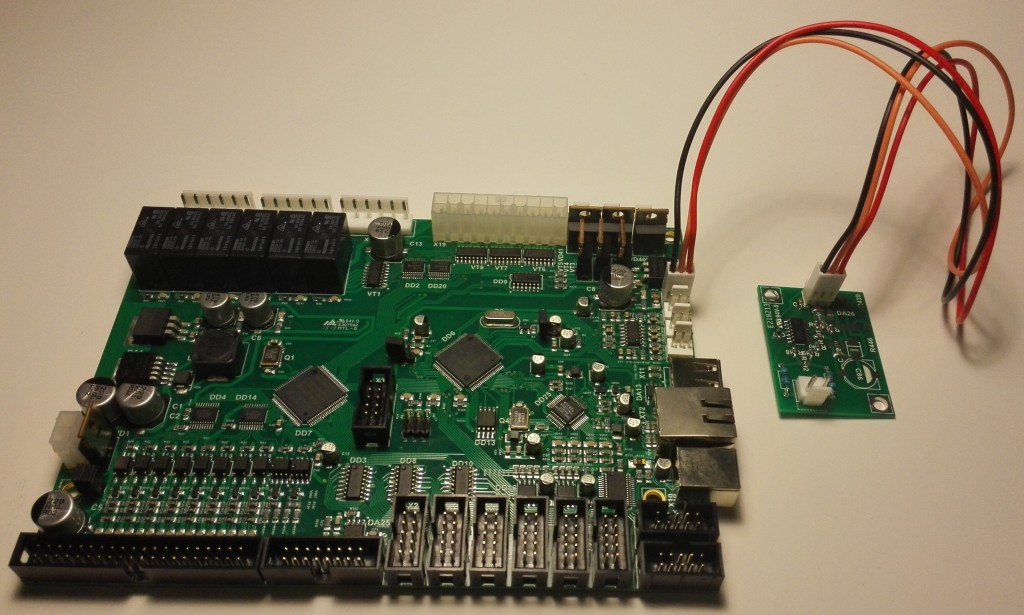

Connection of THC addon to ET1 Ethernet control board is shown below. 12VDC power supply for THC addon board can be taken directly from ET1/ET5 ADC input connector.

Schematic design of differential amplifier is very simple so you may consider DIY as well.