Tangential Cutting

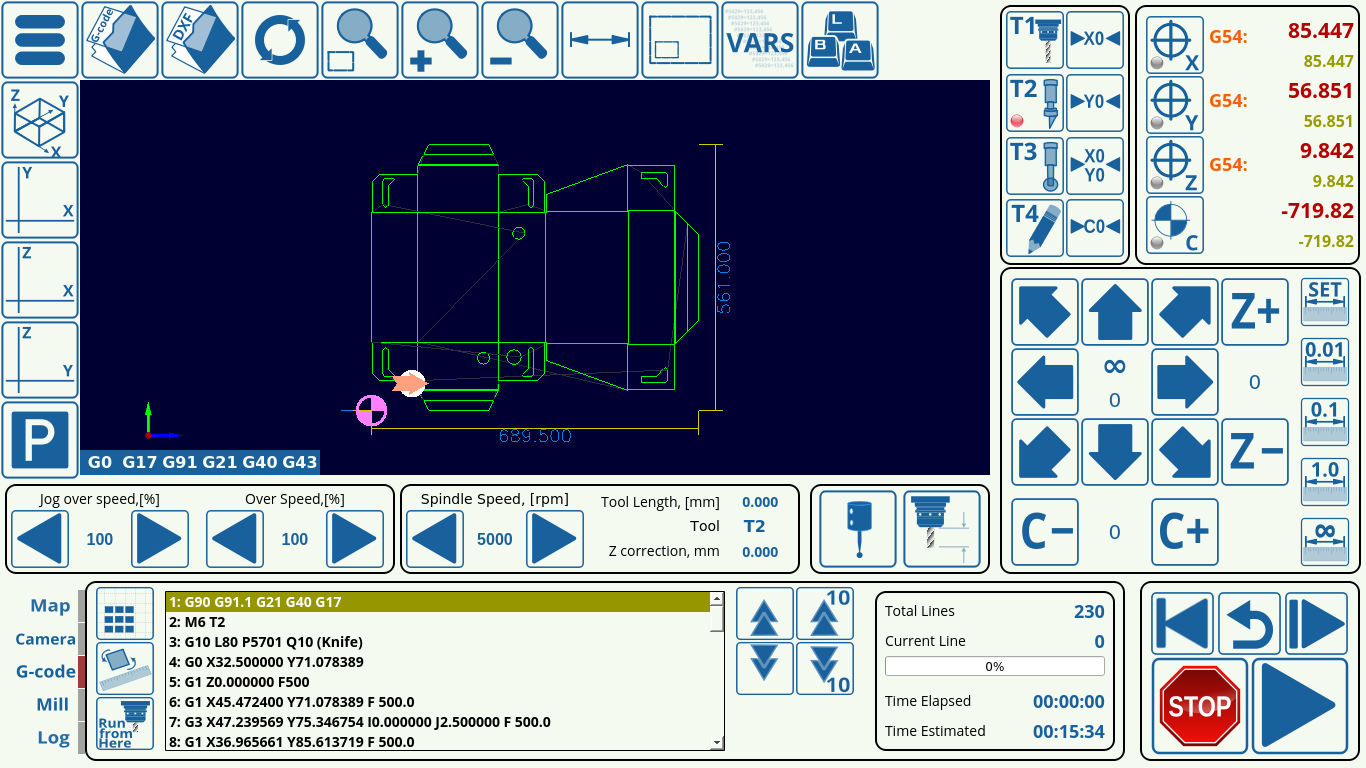

MyCNC CNC control software supports tangential cutting control, providing an all-in-one solution for any cutting needs. No special CAM programming is needed to generate the necessary rotation/lift G-code commands - the myCNC software generates the tool path automatically upon importing the DXF/HPGL file.

The myCNC application supports a number of tangential cutting features, including

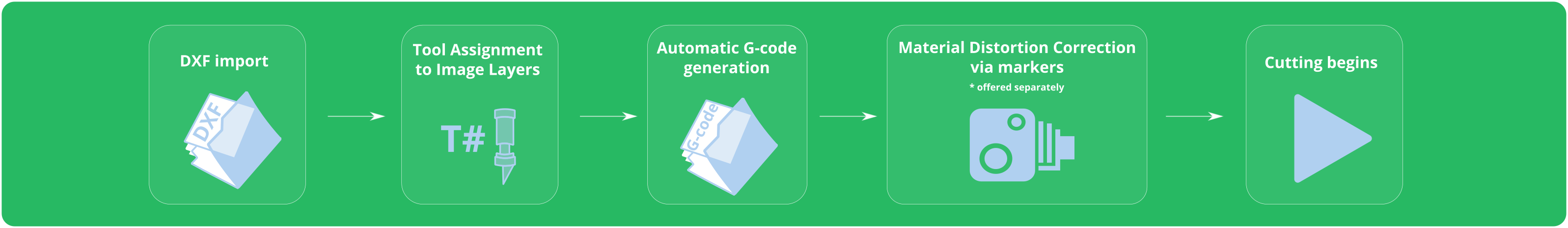

- DXF/HPGL import

- Quick tool assignment based on layers in the original DXF file

- All-in-one solution for complex systems - able to run a job with both tools that require tangential cutting control (knives, half-knives, creasing wheels), and tools that do not (spindle, camera) while only loading in a single DXF file.

- Distortion and shift correction via marker recognition using the CNC Vision system (offered separately)

Tangential cutting is thus typically done via the following steps:

A video with a quick recap of technology assignment and DXF import for tangential cutting is available:

Standard 2 axis G-code files (X and Y motion) are suitable for tangential knife cutting. It's possible to use 2D DXF files for tangential knife cutting as well. In case several cutting heads are used (tangential knife, creasing wheel, half height knife, 45 degree knife, spindle, marker, laser pointer etc) each tool should be drawn in its own separate layer. DXF import allow to assign a tool for every layer and to set up the lift height, cutting height, feed rate and other parameters for every tool.

Once tangential cutting control is activated, myCNC CNC control software will automatically generate the output G-code file, inserting all the necessary tool change and tool raise/lower macros.

The following videos show the myCNC controller system being used on tangential cutting machines:

Visit our documentation wiki page on tangential cutting and the CNC Vision system for more information.

Robots retrofit can be made with myCNC control.

Here is Robotec robot controlled by our new myCNC-ET15 board. Retrofit isn't finished yet, lots of work to do.

Next steps are robot kinematics implementation and "teach" mode.

to be continued...

CNC Laser Cutting machine

For laser cutting control myCNC has

- Torch Height control (THC) for laser

- Initial Height Control (IHC) - probing and set cutting height before cut, Lift up Laser Head after cut

- Laser Power modulation depends on cutting speed to reduce sheet overheat on corners

Laser cutting profile

The myCNC Team provides the experimental laser cutting profile Y1366L on request. Note that at the time of writing the manual (November 2021) the profile is currently under development and is not yet intended for final release.

The main profile screen is displayed below:

The profile allows to select the following:

-

Cut speed

-

Height

-

Power (percentage)

-

Frequency

-

Duty

-

Gas Type, Gas Pressure

-

Time

-

Dynamic Frequency, 1 and 2

The profile also allows to use up to three pierce steps, and store up to 8 presets for laser cutting.

The modes can also be switched using the G130 command, for example:

G130 P1 G130 P2