CNC Camera Vision (Optical Registration Mark Reading) System

The myCNC Camera Vision system is a low-cost feature-rich integrated solution suitable for a variety of uses on CNC machines. The Vision system allows for quick location of registration marks on the working material, automatically adjusting the working path by accounting for shift, rotation and stretch of the material. The z-axis mounted camera takes advantage of the built-in myCNC software features to provide a seamless experience in manufacturing and quality assurance tasks, and allowing to compensate for inaccuracies of the cutting and printing processes.

The CNC Vision system is implemented through the use of a CNC Vision System license (for a Digitally Aligned Cutting System), which can be purchased in our Online Shop. Note that the use of camera through myCNC software is possible without purchasing the Vision System license, however the license is necessary for registration mark recognition and distortion correction.

NOTE: The CNC Vision functionality is currently supported on Linux systems ONLY.

Main Features:

- Optical Registration Mark Reading allows for easy material loading, providing a simple way for automatic cut adjustments by using software triangulation

- Camera system can be mounted next to the machining unit, with myCNC software

- Intuitive user interface

- 2 MP resolution FullHD IP Camera

- Sony IMX327 WDR CMOS image sensor, 6-22mm variable focus, 1/2.5'' format, CS Mount, Auto IRIS, IR-CUT, 1080P @ 25fps.

- Long unattended runs are made possible by automatically searching for the markers that are not within the initial field of view of the camera

- Compatible with both USB and LAN connections (LAN cable included in the kit)

- Two camera configuration kits in stock

- Quick and easy calibration system for the registration marks

- Adjustable levels of marker parity with the reference marks (allows for the system to adapt when markers are drawn on different surfaces)

- Support of a large number of registration marks for increased precision during the triangulation process

The Camera Vision kit includes:

- Industrial PC with myCNC software preinstalled

- Camera system

- LAN cable

- Mounting plate

- Power supply

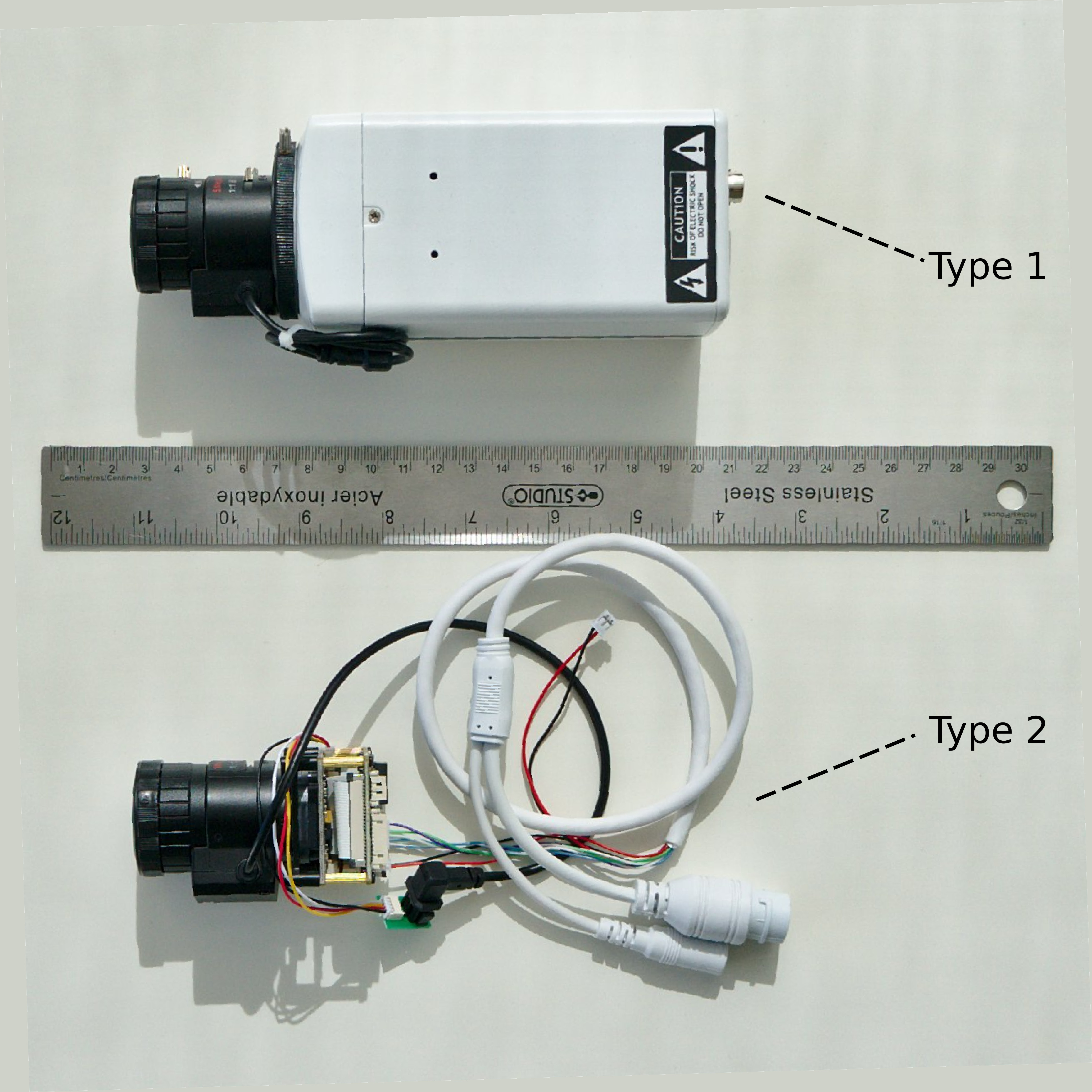

Camera Types

There are two types of cameras sold in the CNC Vision kits, both with similar lens and sensor specifications. Depending on the customer's needs, either of these cameras can be used.

For a full overview of the CNC Vision system's setup and calibration process, please visit our CNC Vision Setup page. To buy the CNC Vision kit, please visit our Shop page.

Below is a video from our client with a CNC Vision system already implemented: