ET6 control board firmware reflash

WARNING: Unlike updating the myCNC software, the firmware CANNOT be downgraded after a reflash. The myCNC team recommends reflashing the control board firmware as a last resort only, and recommends seeking an explicit confirmation from the support team that the firmware reflash is warranted in order to avoid issues.

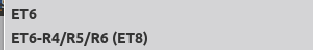

NOTE: Make sure to select the firmware for the correct version/revision of your board! Firmware for ET6 boards R1-R3 and ET6 boards R4-R6 (also known as the ET8) are DIFFERENT. Flashing incorrect version of the firmware will result in a non-functional board. If you're unsure of your board version, please contact myCNC Technical Support prior to the reflash:

myCNC-ET6 reflashing procedure may take about 3 minutes.

To reflash the board:

1. Plug 24V DC supply

2. Plugin micro-USB cable to ET6 & Host Computer with myCNC software installed

3. Close (short) jumpers J5(reset) & J6(programming) on myCNC control board

4. Open (remove) J5 jumper.

5. Open myCNC software on the Host computer,

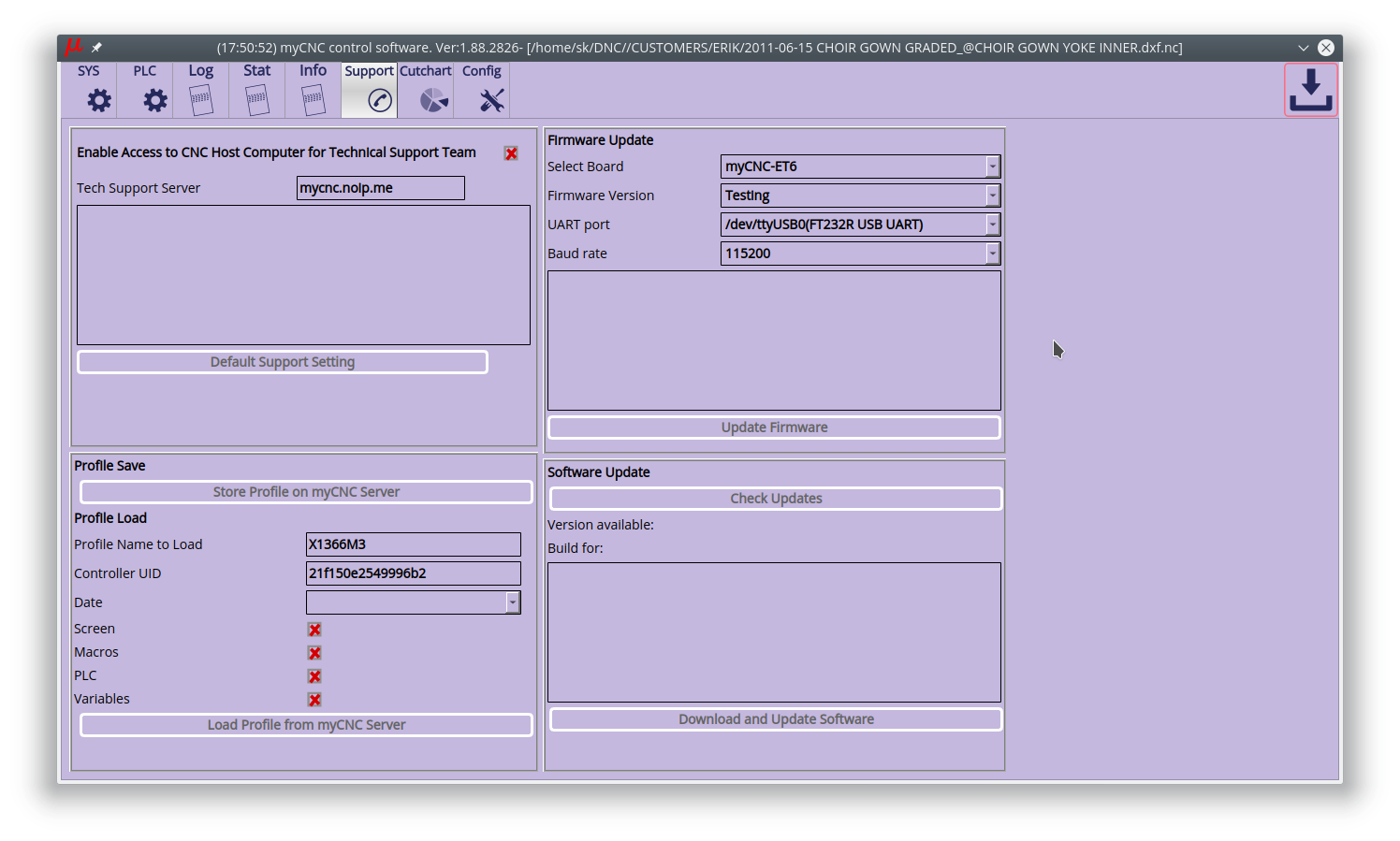

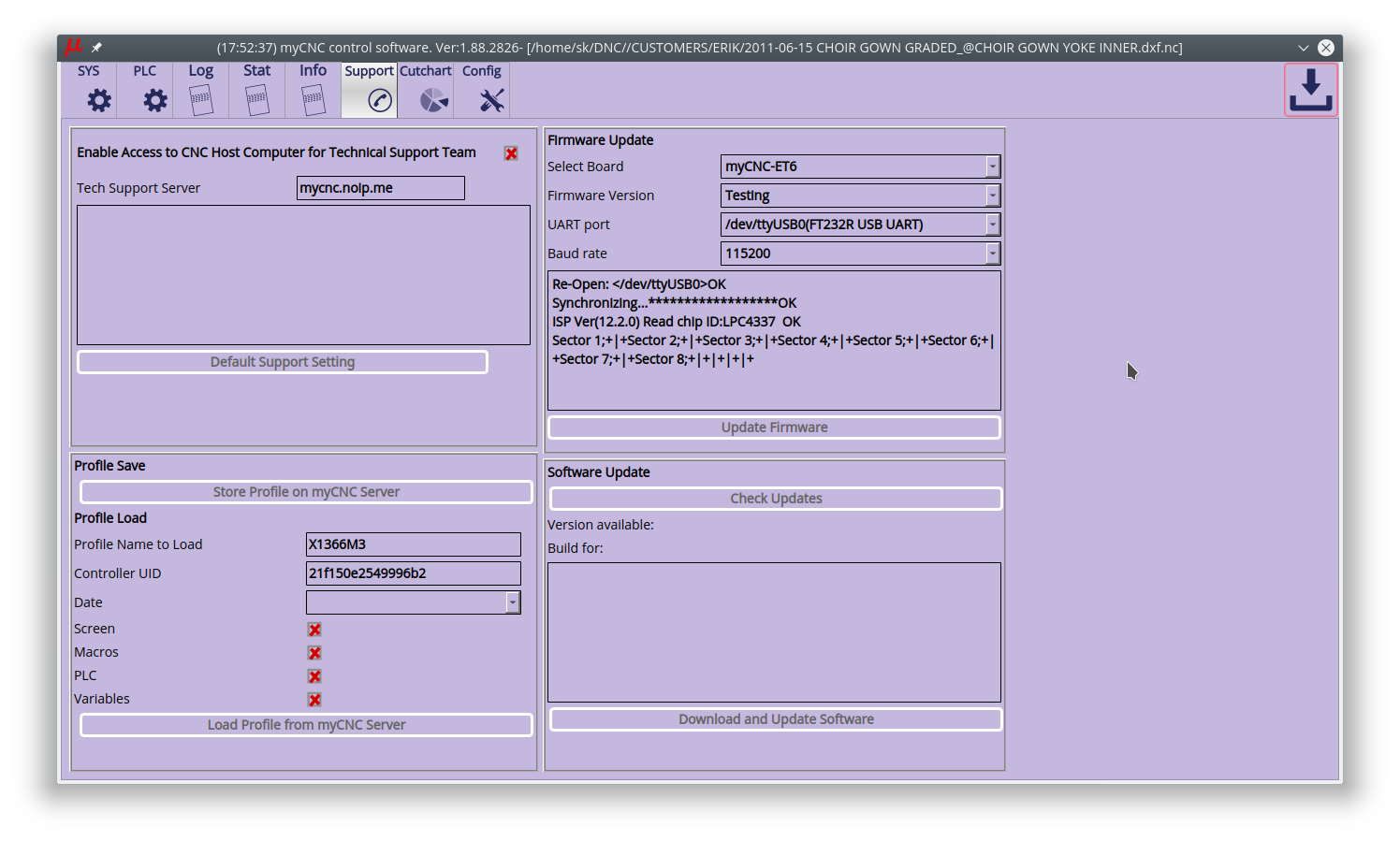

a. goto Configuration Tab -> Support Tab

b. Set "Select board" set to "myCNC-ET6"

c. Select "Firmware version" from "Release", "Night build" or "Testing"

d. Set *UART port* to port with FT232 attached

e. Set *Baud Rate* set to "115200" for ET6; other baud rate can be selected in case of problems on 115200 speed

6. Press "Update Firmware" button, Firmware download and reflashing process will begin.

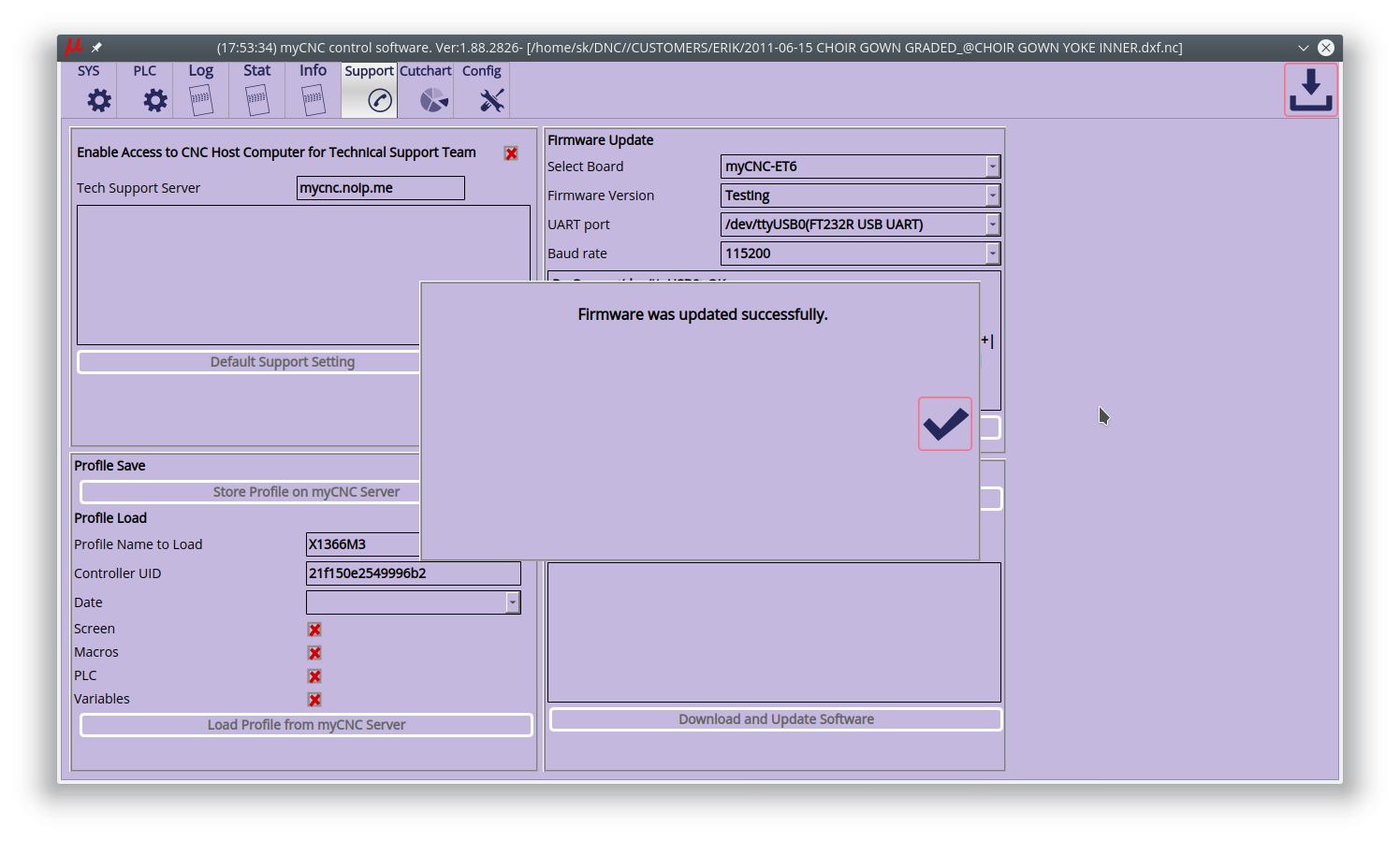

7. Sector 0 will be written at the end of process. After firmware process finished, a popup message will be shown.

8. Remove all jumpers (J5, J6) and restart the board. To restart the board you need to either repower ET6 or close the Reset jumper (J5) for 1 second, then release it. The board will be restarted.

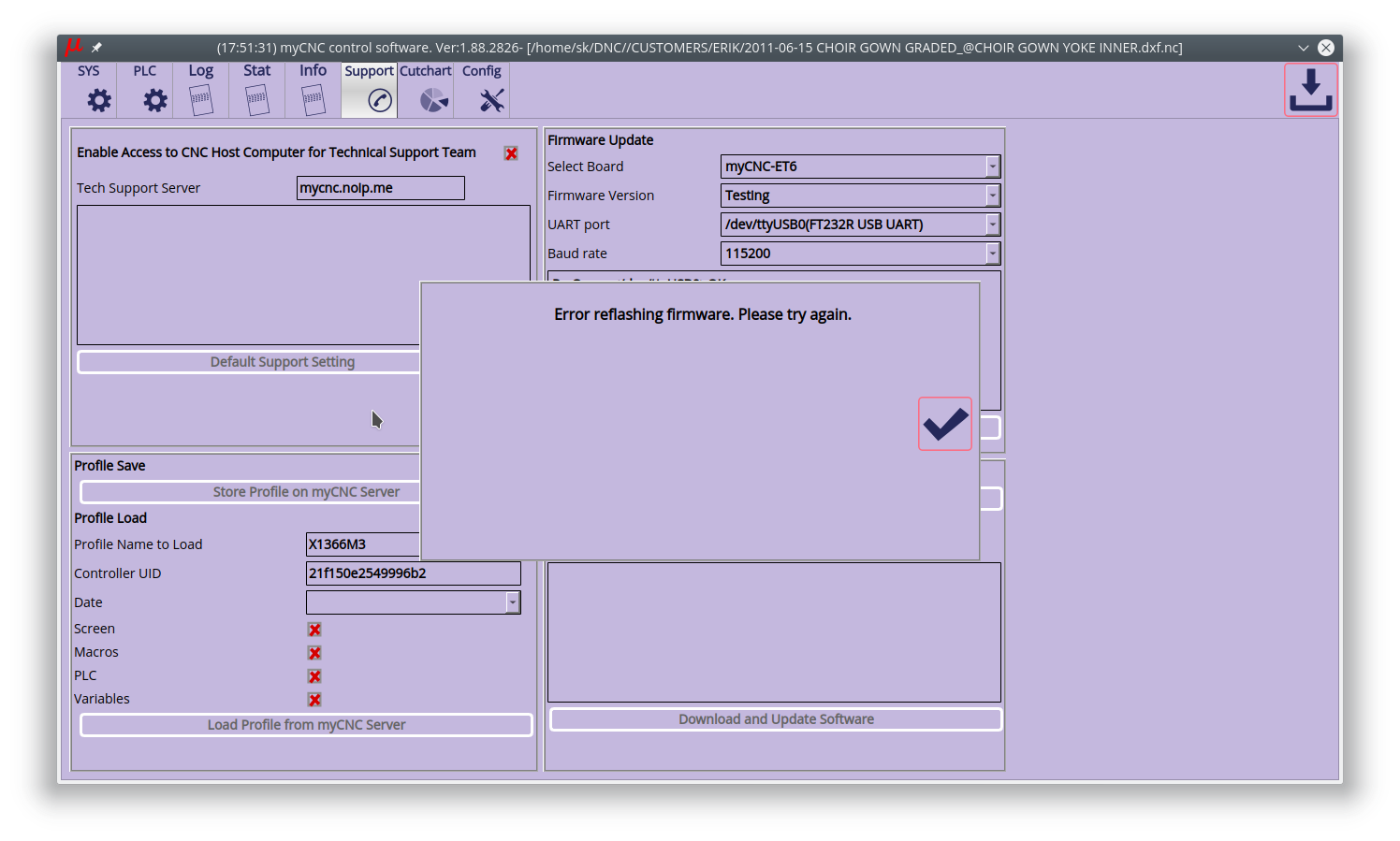

In case the reflashing process failed, you will get a popup message.

If this is the case, please repeat procedure from #3

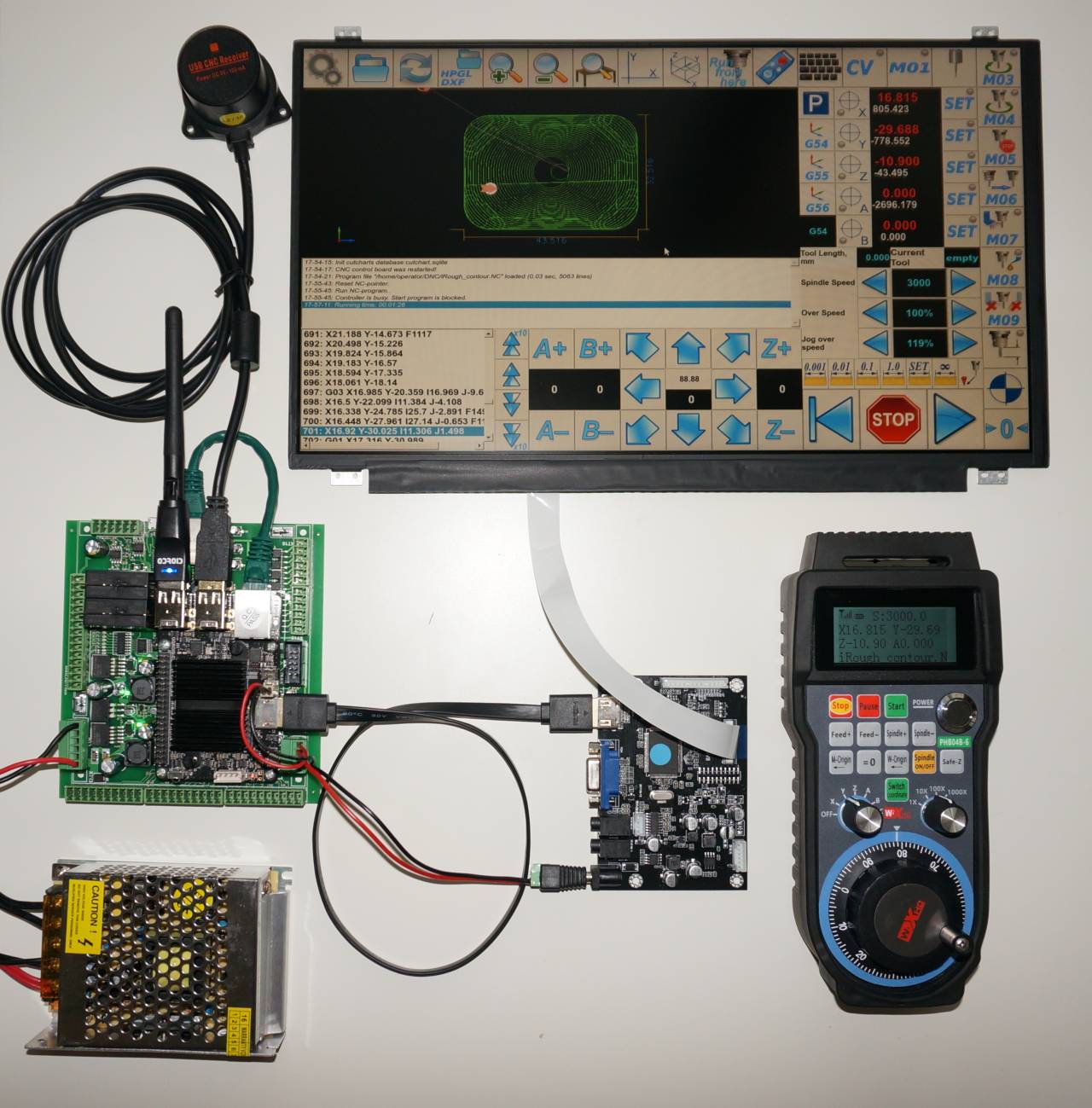

myCNC-ET6 controller board

myCNC-ET6 controller specification

| Number motor outputs |

6 |

| Motor driver outputs |

pulse-dir, |

| Maximum pulse frequency |

3 MHz |

| Inputs |

8x galvanic isolation, |

| Outputs |

2x - relays 10A, NO/NC contacts |

| PWM outputs |

3x - open collector, 24V, 0.25A, |

| DAC output |

1x - 0...10V (for spindle speed control and relative applications) |

| RS485/RS422 |

1x RS485 half-duplex serial communication, |

| Power supply outputs for control computer |

2x DC-DC converters 5V 1.5A |

We moved connectors description to our Wiki

myCNC-ET6 board contains built-in DC-DC converter and mounting holes to install and power-up Odroid/Raspberry computer board. Standard monitor with HDMI can be connected to Odroid-C2 computer board. Screen resolution up to 1920x1080 (Full HD) supported. Fully functional Ubuntu 16.04 Linux and myCNC control software installed on the computer. NC code files can be uploaded to the computer through Wifi (Samba Server, FTP Server installed on the computer) or USB disks.

We can offer affordable 10" or 15.6" screen with resistive touch to build a complete stand-alone CNC control kit.