The latest release of myCNC software (v1.88.5353) features support for a ruler with grid lines in the visualization window:

This functionality should make it easier for the user to visualize the size of the G-code program they are working with. The colour of the ruler can be changed in Settings > Config > Screen > Visualization Colors:

Stay tuned for more updates!

Clients in Poland can now purchase the myCNC controller boards from our partners over at PIVEXIN TECHNOLOGY. Controller support for the controllers purchased from their website will also be provided directly by PIVEXIN.

Please visit their website at pivexin-tech.com/, or contact them at

Stay tuned for further updates!

For our clients with plasma cutting machines, certain third-party stores carry THC Z-axis torch lifters that are driven by a DC motor (like the one pictured below):

Such a device is a popular choice with some of our clients, as it allows for an affordable THC solution without sacrificing too much in the way of accuracy.

The myCNC team is ready to provide a driver board for connecting the torch lifter to the ET7, as well as the additional initial positioning procedures and a modified THC process to work with such a lifter.

For more information on the driver board as well as the modified PLC commands, please reach out to the myCNC team via our Contact Us page.

Hello eveyone,

In the latest myCNC update (version 1.88.4910) we have added a new attribute called "pressed-delay-xxxx" for the "direct-run:" action. The attribute allows you to define time (in ms) that the the on-screen element (button, etc) must be pressed for, in order to initialize the direct-run action. This can be used to protect the machine from accidental presses on touchscreen/keyboard/mouse.

The attribute also works for the following actions:

- soft-plc-run

- soft-plc-stop

- soft-plc-run-confirm

- soft-plc-stop

- plc-run

- direct-plc

- multidev-plc-run

- switch-cnc-gvariable

as well as program start via the "player-play" type commands.

To find out more about XML editing to insert the necessary attributes into your profile's UI elements, please consult the following manual in our documentation:

The update also brings some bug fixes:

- Fixed a bug that would sometimes cause crashes on large-size G-code files

- Fixed a visualization bug for work position that was affecting some program versions

Stay tuned for further updates!

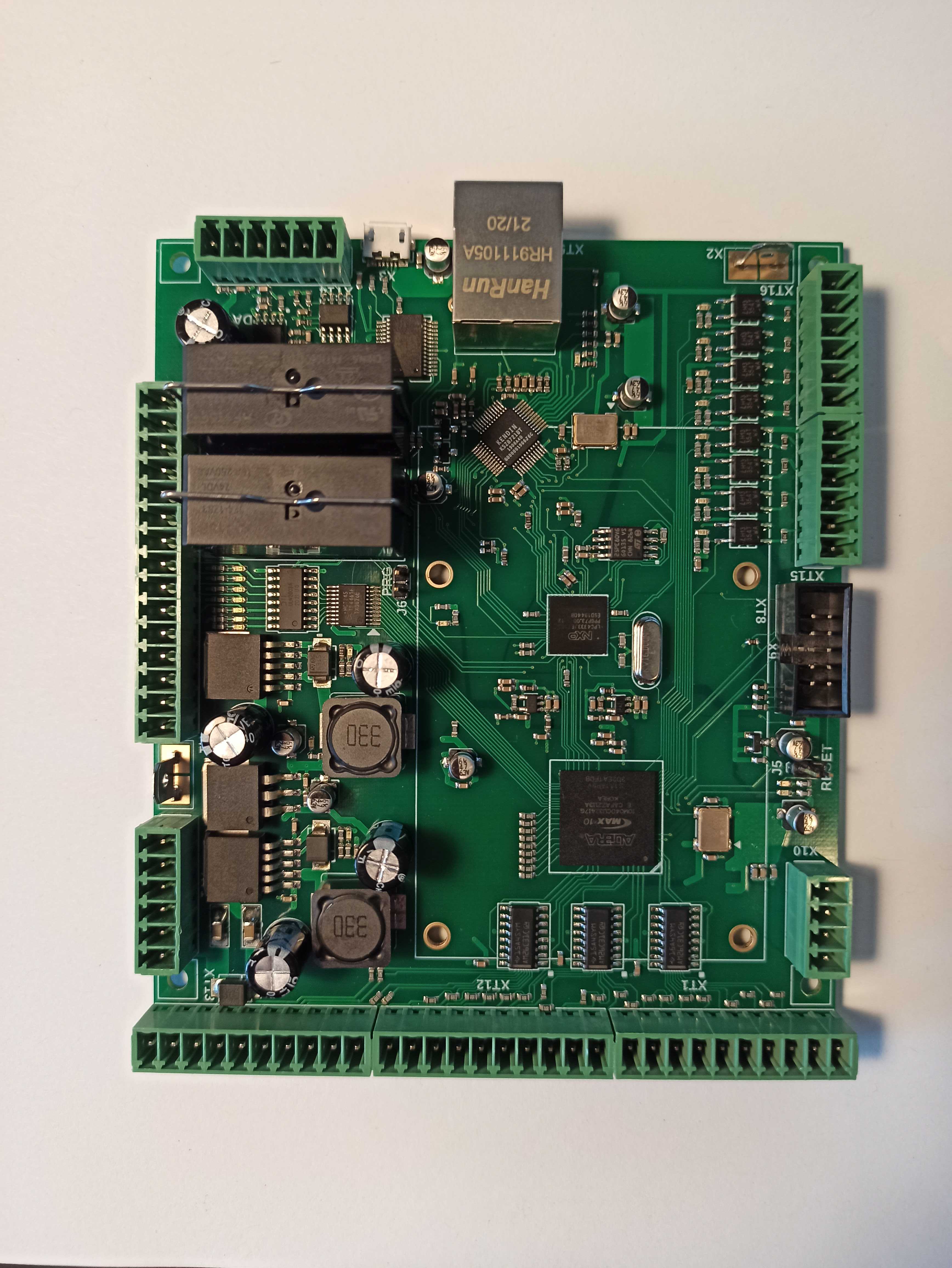

The latest update for myCNC software (ver. 1.88.4855) brings support for the ET8 controller.

The ET8 is an alternative version of our ET6 controller, with a different microchip architecture. For most intents and purposes, these perform in the exact same manner, and the ET6 documentation can be used for setting up and programming the ET8.

For further information on purchasing the ET6/ET8 controllers, please contact the myCNC support team.

Stay tuned for further updates!