Some updates on the latest developments from the myCNC dev team:

We have added the capability to control an additional independent axis using a myCNC controller to our software. Such an additional axis can be controlled simultaneously with (and independently of) the main program - this includes manual movements, MPG control and positioning instructions from within PLC commands.

This new functionality is planned to be utilized for applications such as grinding machines, laser cutting (to have a Z-axis with tracking and positioning simultaneous with regular program execution), oxy-fuel cutting (piercing operations with simultaneous XY movement), and others.

The feature is currently being tested, and should soon be available to the public.

Stay tuned for further updates!

The latest myCNC update includes fixes for Modbus device mapping for exhaust control.

Previously, exhaust control worked only for native outputs with addresses 0 to 31. Upon requests from our users, we have expanded this functionality so that it is now possible to use Modbus devices, and to map outputs to the outputs' address space.

This change allows the users to use the outputs numbered from 31 upwards. These outputs have already worked when used in the PLC commands, but should now also function as expected for the Exhaust/Extraction Control settings.

Stay tuned for further updates!

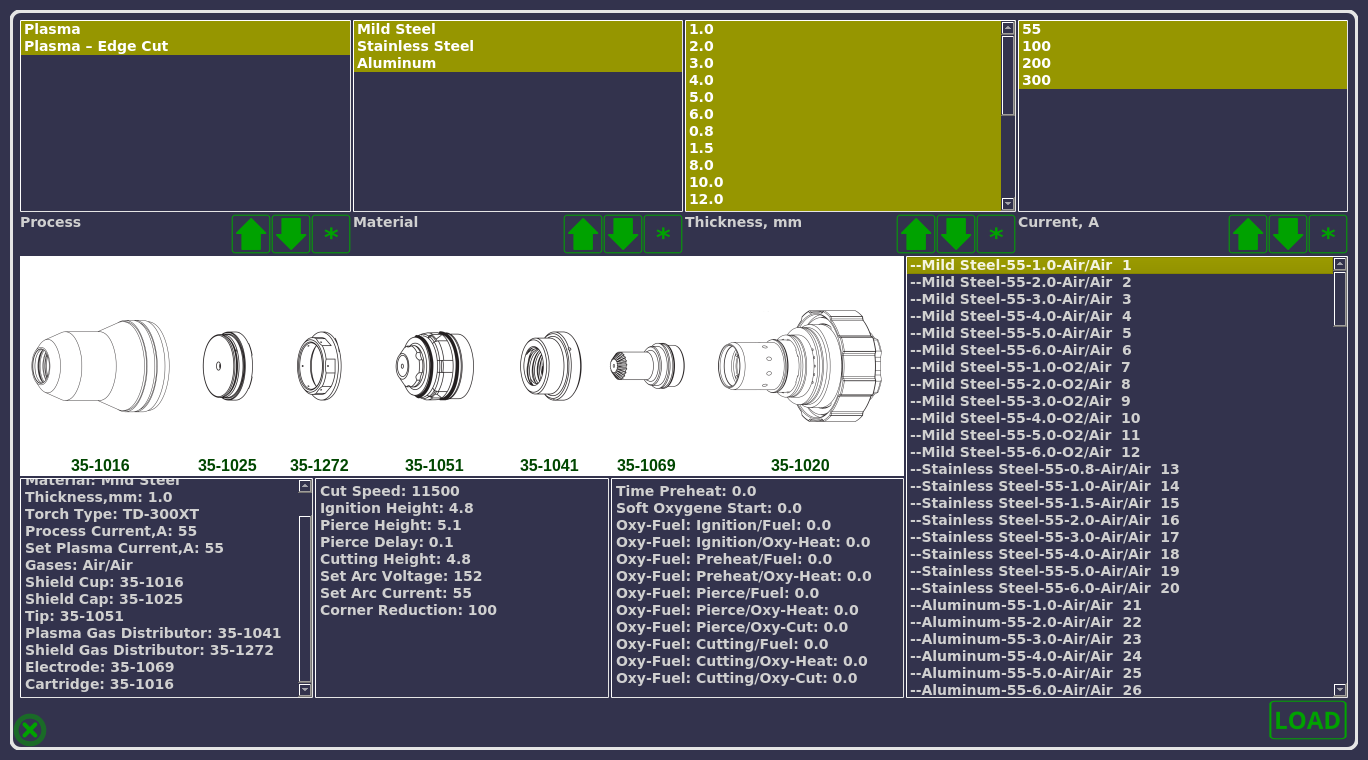

New myCNC cutcharts for the Auto-Cut 300 XT power source are now available to download.

The cutcharts include settings for a range of materials and material thicknesses, as well as a separate option for an Edge Cut.

To download, simply head over to our Downloads page.

Stay tuned for more updates!

Hello everyone!

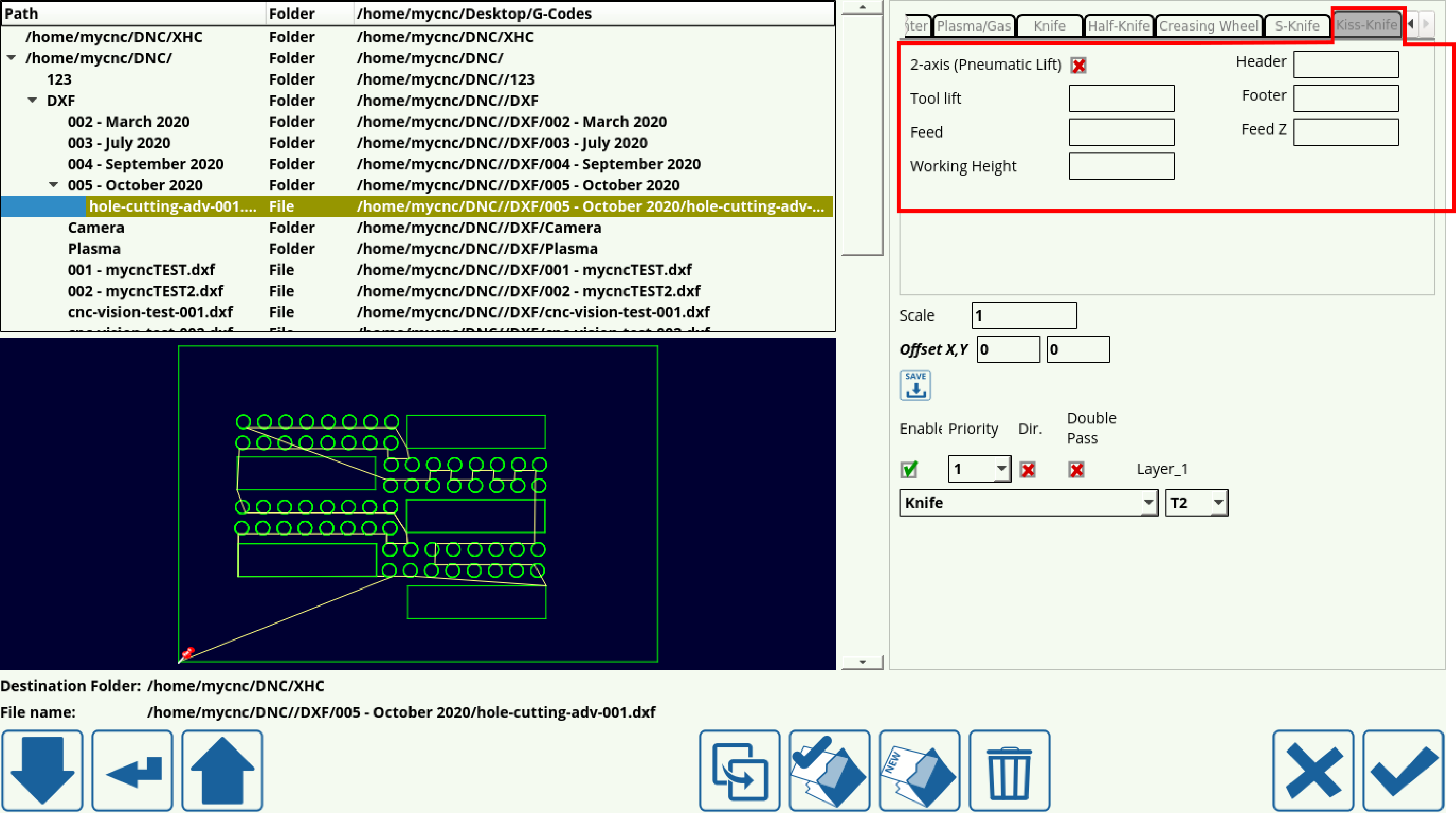

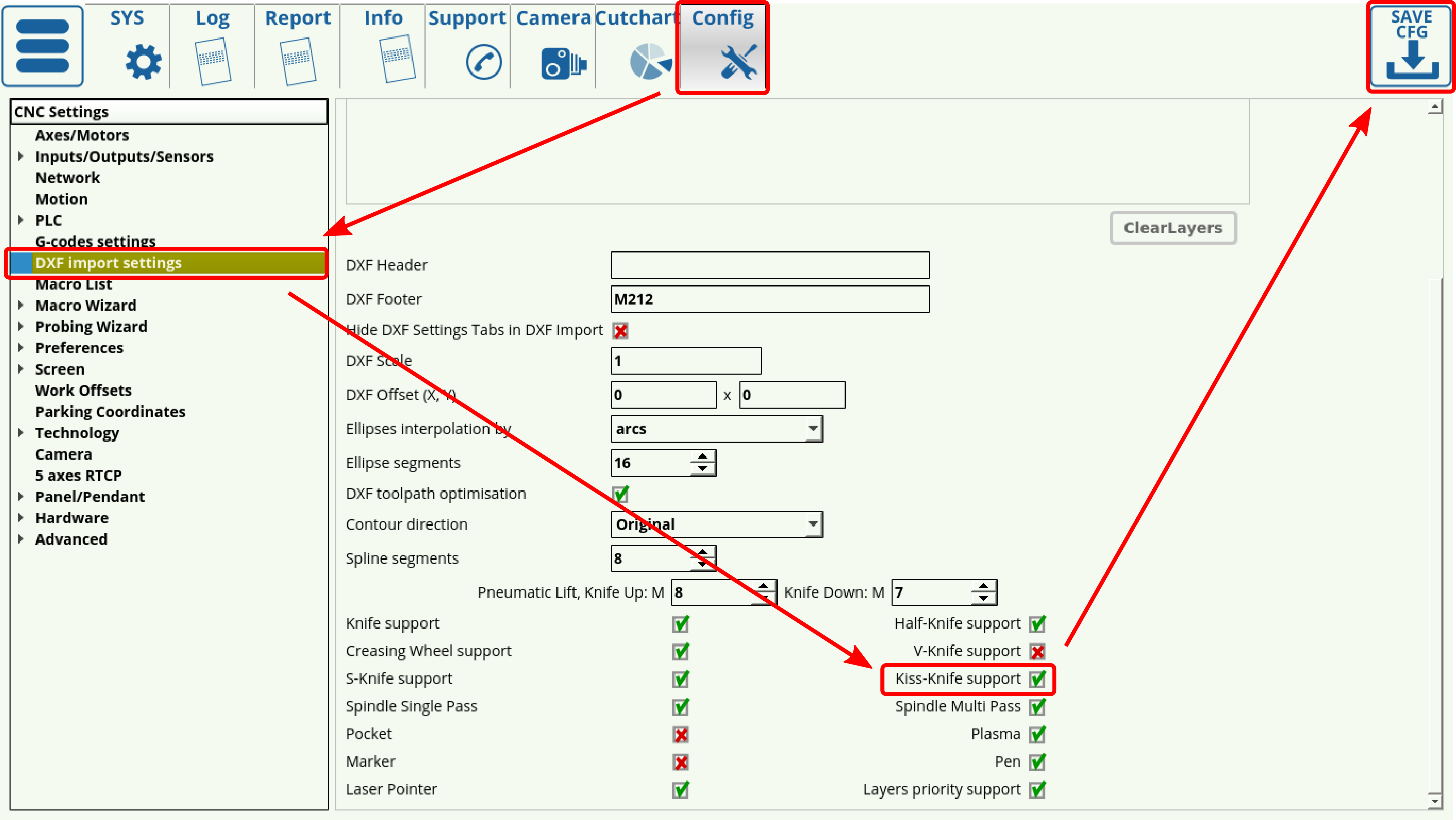

The recent myCNC update brings support for kiss knives in DXF import:

Kiss cutting knives are useful for applications such as sticker cutting, allowing for precise depth of cut separate from the main tangential cutting knife.

To enable the kiss knife DXF import functionality, update to myCNC version 1.88.4231 or higher, then head into Settings > Config > DXF Import Settings and make sure that the Kiss-Knife support option is turned on.

Stay tuned for more updates!

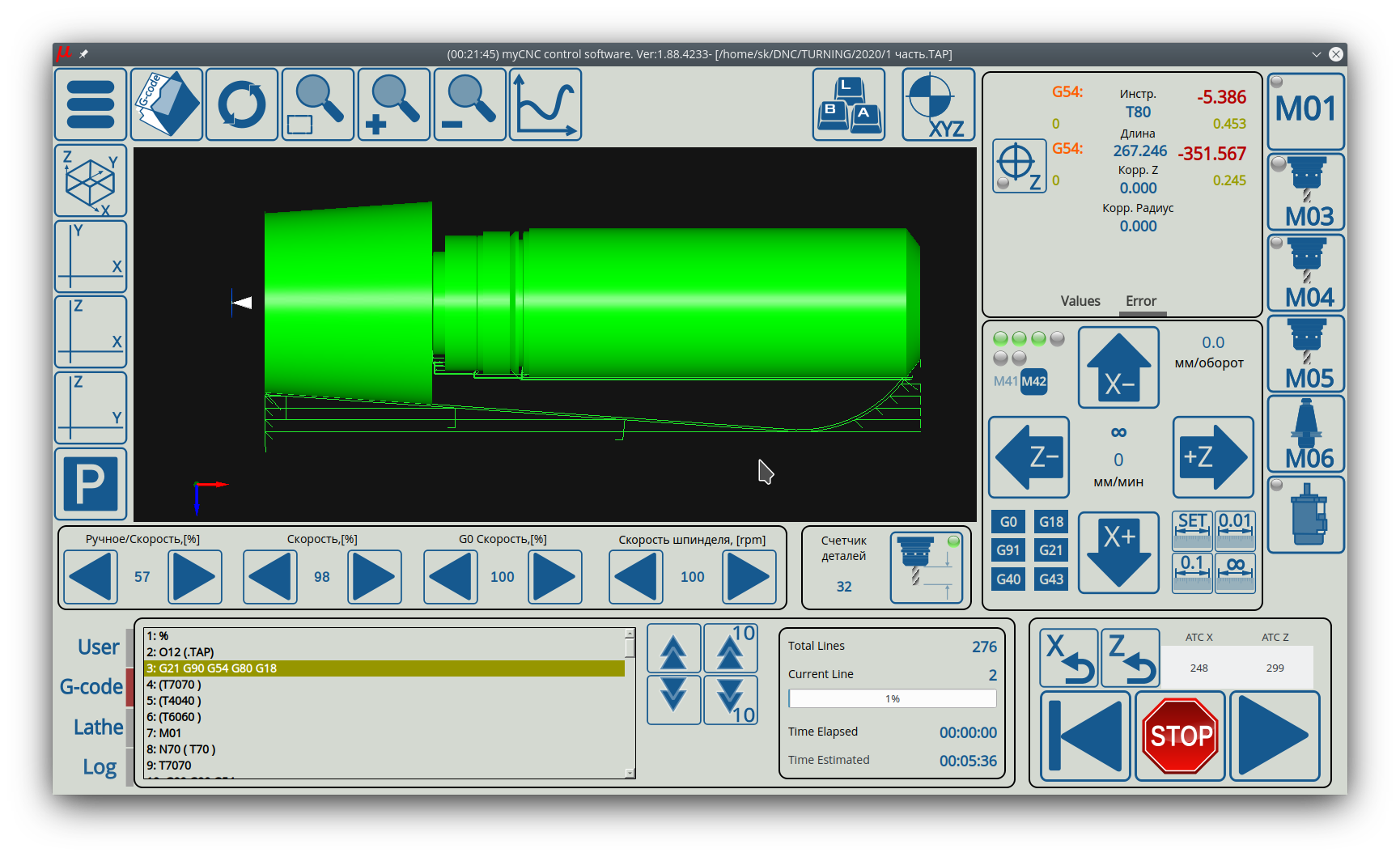

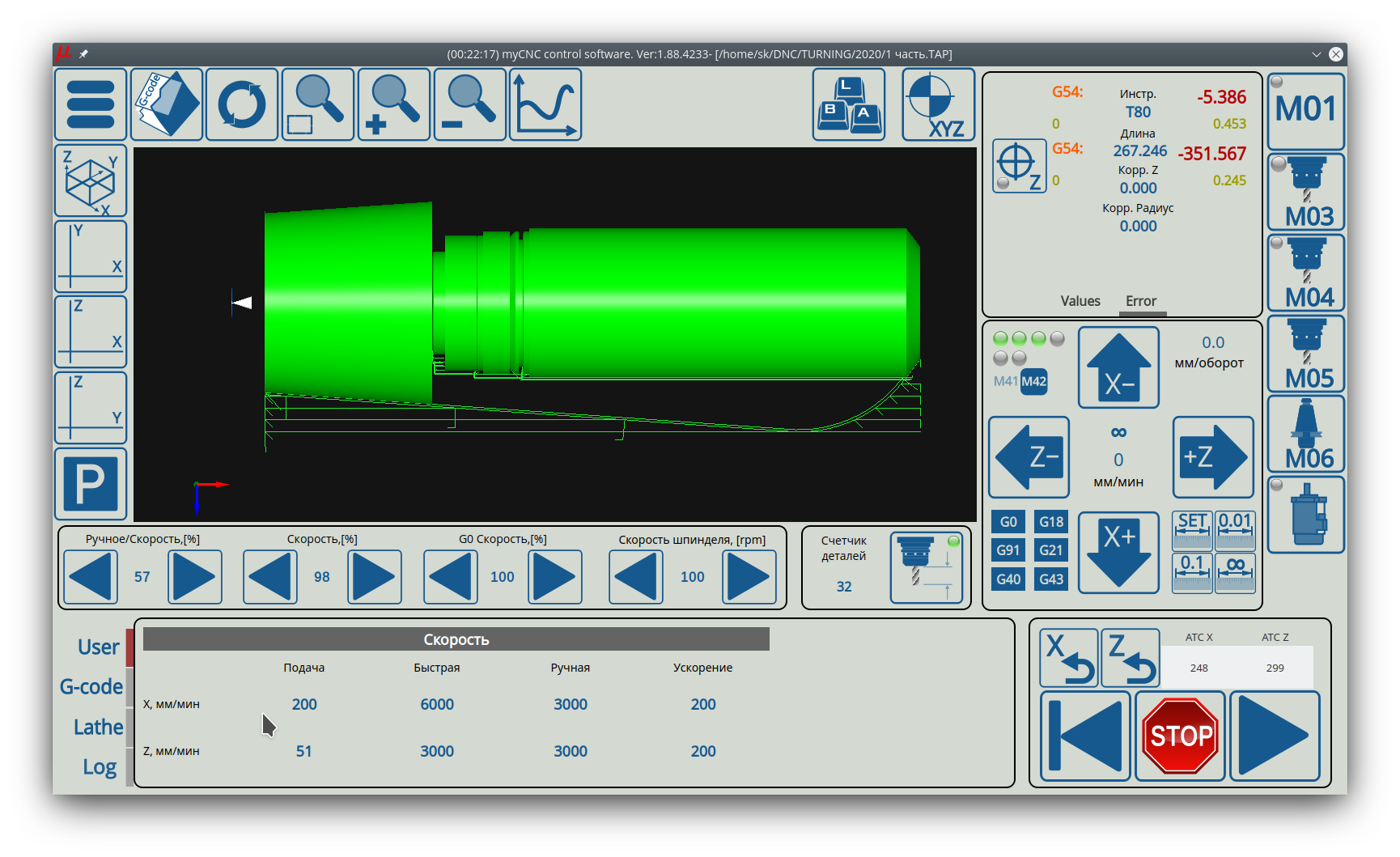

The myCNC team is currently developing a dedicated lathe profile.

The screenshots below represent the current visualization and button layout (WIP). The profile is currently being tested and will soon be available to download from our website.

Stay tuned for further updates!