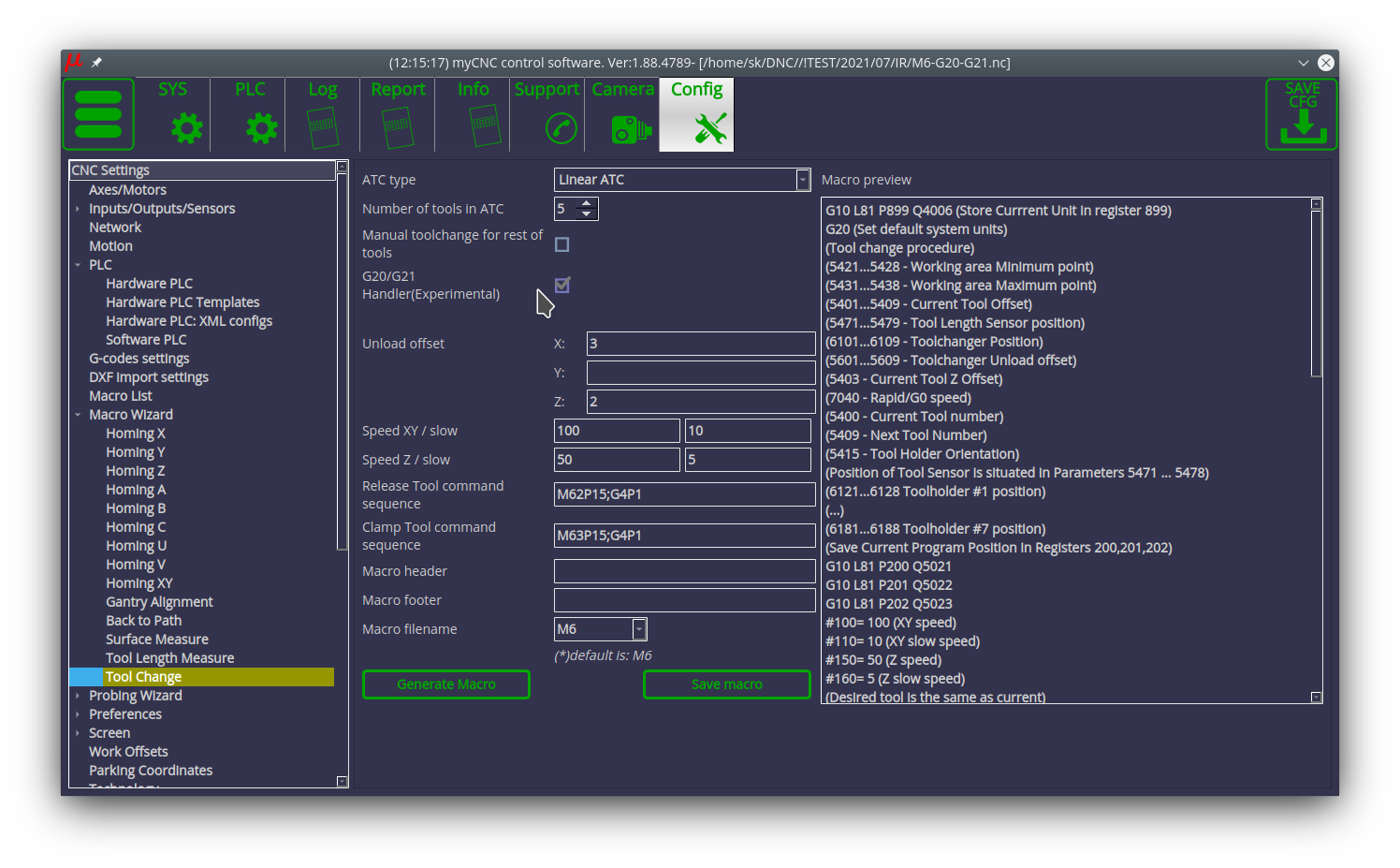

In the latest version of myCNC, we have added the following option to facilitate tool changes in programs using both G20 (imperial) and G21 (metric) systems:

The G20/G21 Handler (currently in the Experimental stage) allows myCNC to store the units (mm or inches) that the G-code control program is using at the moment that the tool change macro is launched. After the tool change macro is initiated, it will then use the default dimensions selected for the user profile (for example, if inches are selected in G-codes settings, then all dimensions for the tool change will be in inches). At the end of the tool change macro, the current G20/G21 value is then restored.

Additionally, the following fixes have been added:

- Fixed the 3D visualization incorrectly displaying visual program dimensions in millimeters instead of inches despite inches being selected in Config > Screen.

- Fixed the button to toggle the 3D program dimensions on and off

Stay tuned for further updates!

The latest updates have been focused on improving and ironing out inch/G20 functionality within myCNC software.

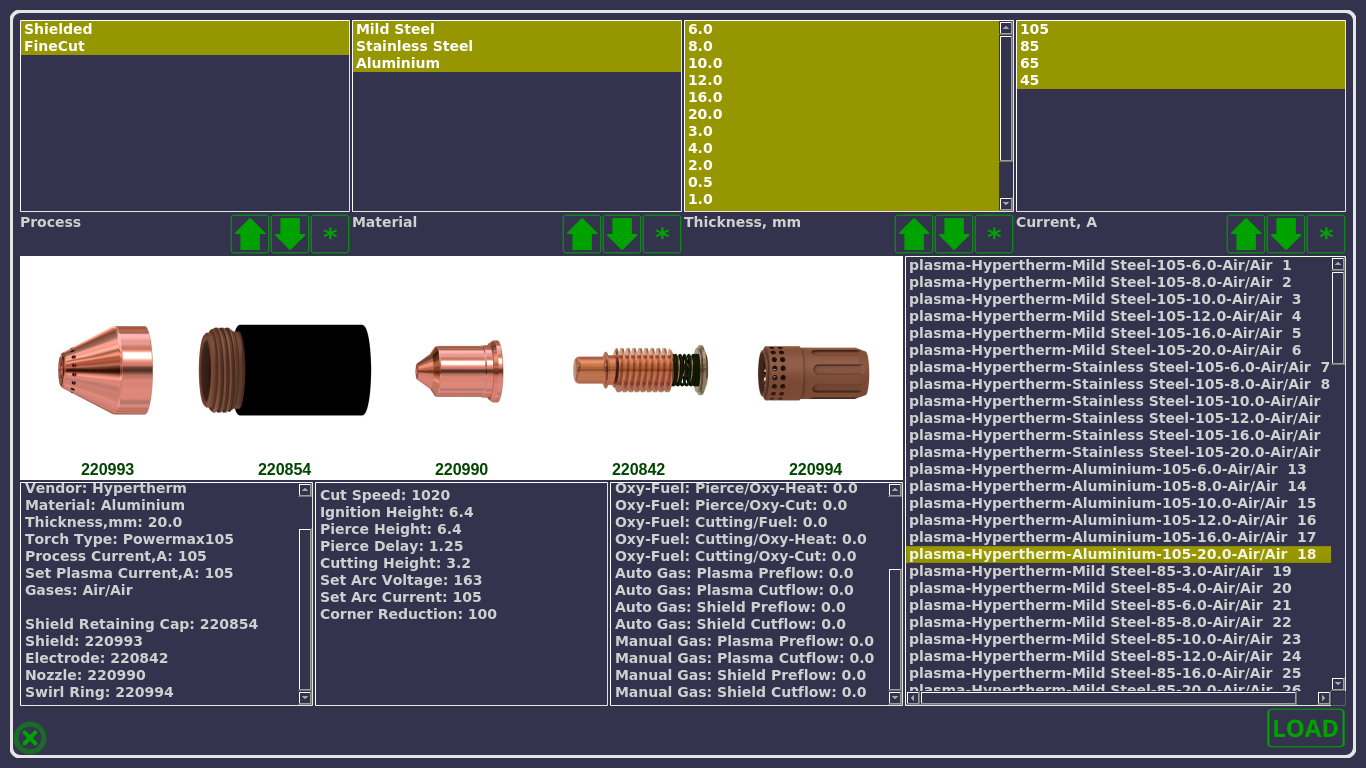

The following inch-based cutcharts have been added to myCNC:

- Powermax 45

- Powermax 45XP (also added the metric system cutcharts)

- Powermax65/85

- Powermax105

- Powermax125

The cut charts will be available to download from our Downloads page. Additionally, an M71 plasma cutting shape library for imperial units is now available on request.

Finally, a number of bug fixes have been implemented for inch/G20 software configurations, mostly focusing on the plasma/gas cutting functionality

- Fixed Return to working point button

- Fixed nesting window, rotation window

- Fixed arc/hole speed

- Fixed tool offsets

- Numerous visual fixes

Stay tuned for further updates!

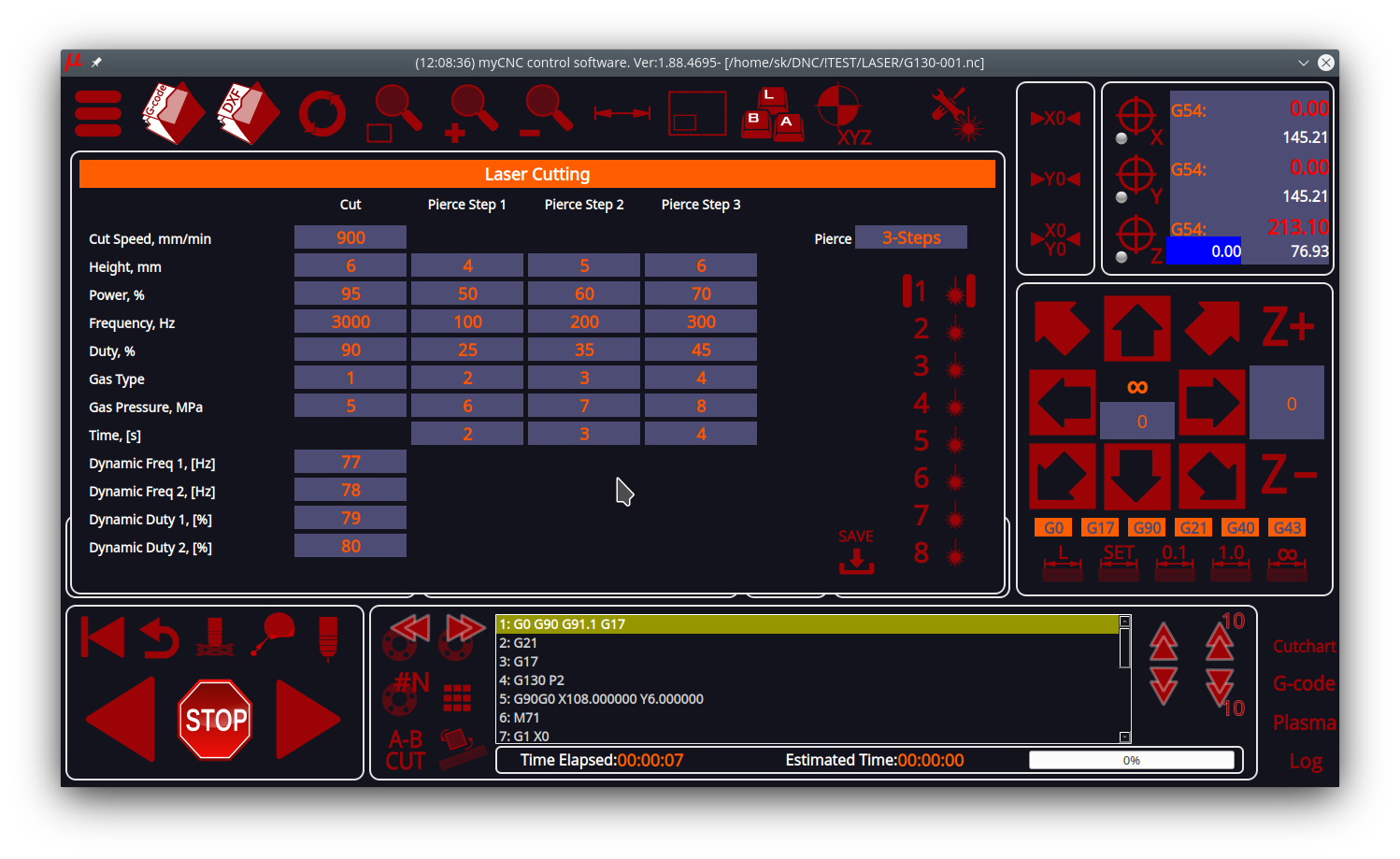

The myCNC team is preparing improvements for laser cutting within myCNC which will take the form of a dedicated laser cutting profile.

Currently, the functionality features a "cutting mode" which includes

- actual cutting mode: speed, height, power, frequency, modulation, gases, etc.

- pierce mode: 1-2-3 step piercing procedure (or without piercing, if the Fly Cut option is used)

Additionally, there will be a table for 8 such cutting modes, which can be switched on the fly from the program by using the G130P1 - G130P8 codes. In cases where it is necessary to first cut the protective film, then cut the metal, or set a different mode on small holes, the G130 command will come in handy.

3) When the "Laser cutting" checkbox is turned on, the system utilizes the built-in pierce-cutting procedure instead of the PLC. This procedure takes in the current mode and takes care of the piercing and cutting steps. The procedure, if necessary, can be run simultaneously with the XY movement.

In the Fly Cut mode, switching the laser/power/modulation ON and OFF is carried out without stopping the movement and is done nearly synchronously with that movement (the expected delay will be about 100-200 μs, that is, at a speed of 12 m/min, the delay in switching the laser ON will be 0.04 mm or lower)

Stay tuned for further updates!

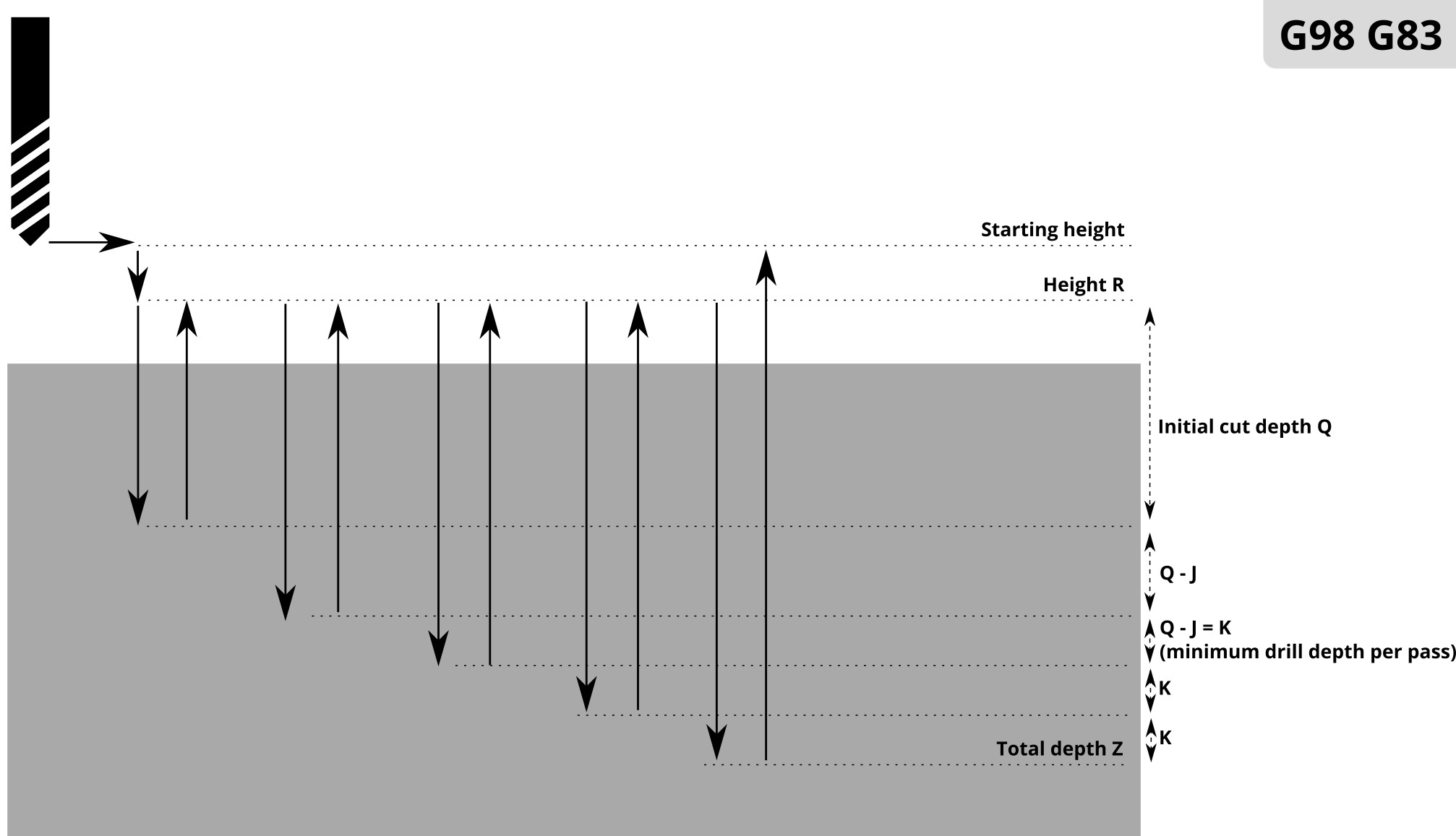

The latest update of myCNC software (v1.88.4586) brings improvements to the drilling cycles within myCNC.

Added the following options:

- G98/G99 for lift to initial height/height R

- G83 for peck drilling cycle

- G81 for single drilling cycle

- G73 for drilling cycle with lift to clearance height

- Drilling lift speed L - useful to avoid drill jams that would occur when lifting at standard jog speed

A sample drilling cycle that is used in the myCNC software is shown below:

G90 G21 G54.

G0 X50. Y50. Z3.

G0 Z10.

M3 S800

G98 G83 X0 Z-9. R1. Q1 P0. F500 L1000

G98 G83 X10 Z-9. R1. Q3 J0.5 K1 P0. F500. L1000

G98 G73 X20 Z-9. R1. Q3 J0.5 K1 P0. F500. L1000

G98 G81 X30 Z-9. R1. Q3 J0.5 K1 P0. F500. L1000

G99 X40.

G80

M5

For more information on drilling cycles, please visit http://docs.pv-automation.com/mycnc/drilling_cycle.

Stay tuned for more updates!

The above video has been provided to us by our client who has been implementing a plasma square pipe cutting setup.

Additionally, we will soon begin providing SheetCam software licenses for those of our clients purchasing a a controller for a pipe cutting machine. We have also recently began to provide a custom myCNC post-processor for SheetCam - more information on both of these options is available on request.

General information on pipe cutting is available in our documentation: http://docs.pv-automation.com/mycnc/pipe_cutting

Stay tuned for further updates!