The latest myCNC update (v.1.88.4543) brings additional kinematics options for different machine configurations.

Improvements are made to the Jewellery section, and two new configurations (XYZ_A and XYZ_B) are added for 4-axes setups.

You can update the application through the Support tab.

Stay tuned for further updates!

For the convenience of our Eastern European clients, the myCNC-ET6 and myCNC-ET7 controllers are now carried by OSA-CNC in Ukraine. Controller support for the controllers purchased from their website will also be provided directly by OSA-CNC.

Please visit their website at osa-cnc.xyz, or contact them at

Happy shopping!

In the latest update of myCNC software, we have added global variable #7696, GVAR_CUTCHART_FEEDRATE_PRIORITY.

This variable will serve as a flag for determining speed priorities in myCNC:

- if set to 0, then the F-code value for speed is used, if present

- if set to 1, then speed from Cutcharts has a higher priority and the F-code is ignored

In addition to this, a new manual on speed priorities has been added to myCNC Documentation: http://docs.pv-automation.com/mycnc/speed_priority

This should hopefully serve as a helpful reference point for all information related to feed rate, simulation speed and other speed priorities within myCNC.

Stay tuned for more updates!

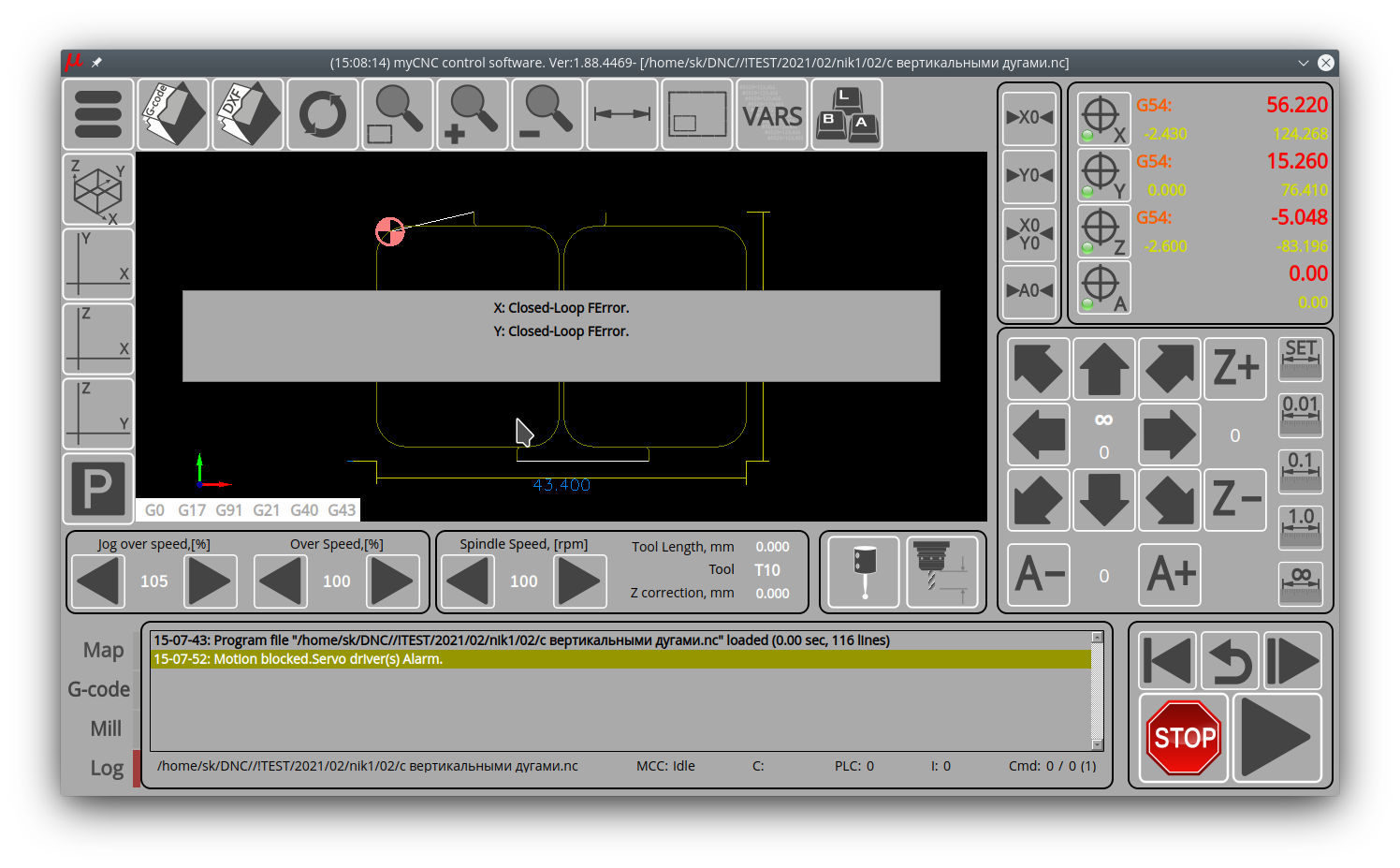

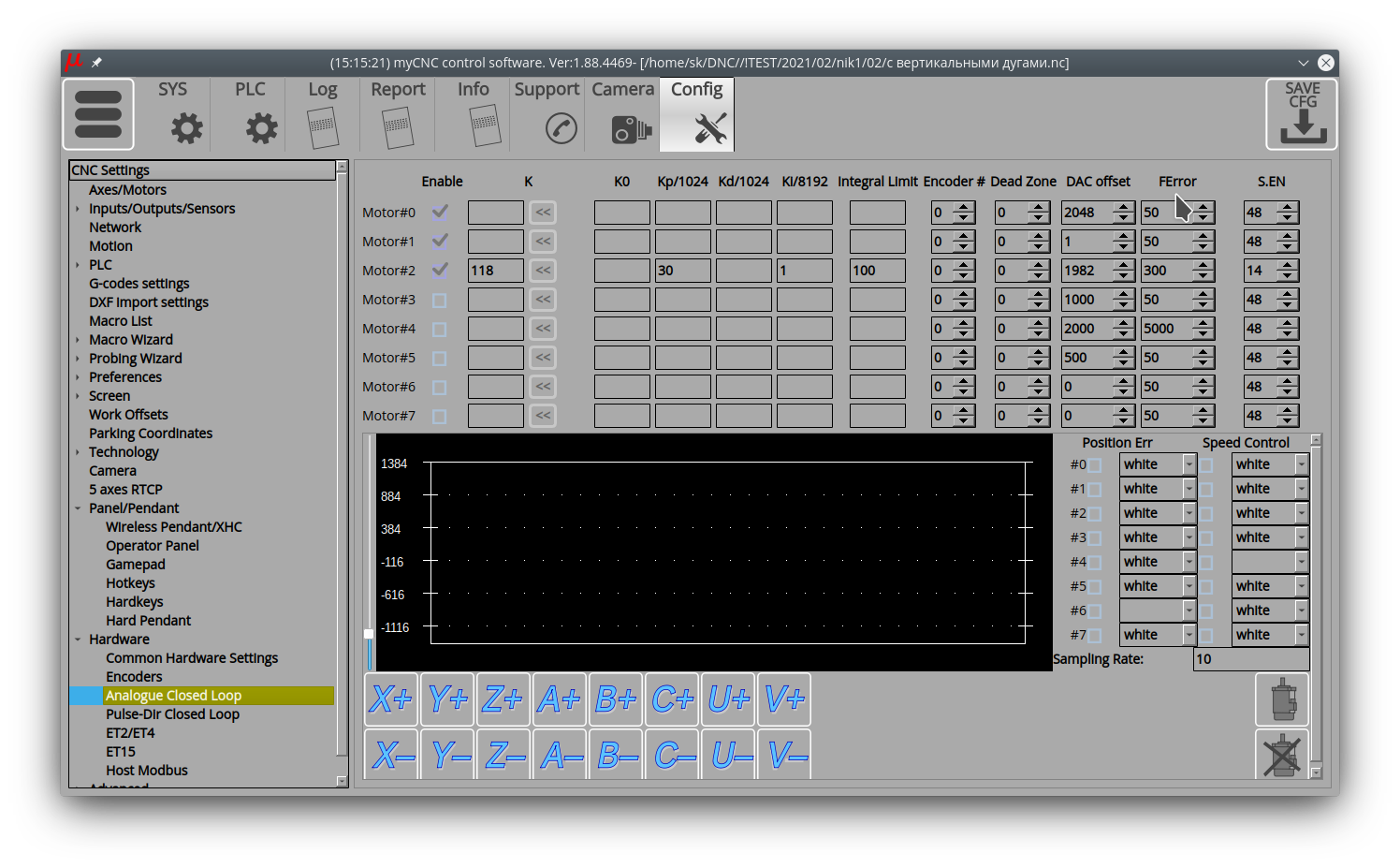

In our latest myCNC update, we are focusing on expanding the existing functionality for closed-loop systems. We are improving handling of the desynchronization FError, the functionality of turning off the servos with the ServoOn signal, as well as the sending of messages and blocking start up in case of errors from one of the Closed-Loop PID regulators.

To allow more granular control over these settings, two additional columns have been added to the Analogue Close Loop tab in our Settings, FError and S.EN (Servo Enable):

The update should be live in the coming days. Stay tuned for further updates!

The myCNC team is currently working on an update to add support for the Hardware Pendant to the myCNC software.

This will feature the same functionality that is currently available via hardkeys/hotkeys from within the software. However, by offloading the processing of the pendant commands to the myCNC controller, response times have been greatly reduced. This should prove to be especially noticeable on older systems, as well as the Raspberry Pi and TinkerBoard computers, and will mitigate the issues in cases where pendant commands would be delayed due to the computer being unresponsive or hanging up due to the computer's hardware limitations.

The next step for the Hardware Pendant feature is the addition MPG wheel support, where the improvements in response time will be even more noticeable.

The feature is planned to be released in the next few days, and will be available to download from our website (https://www.pv-automation.com/en/download) or directly from within myCNC software's Support tab.

Stay tuned for further updates!