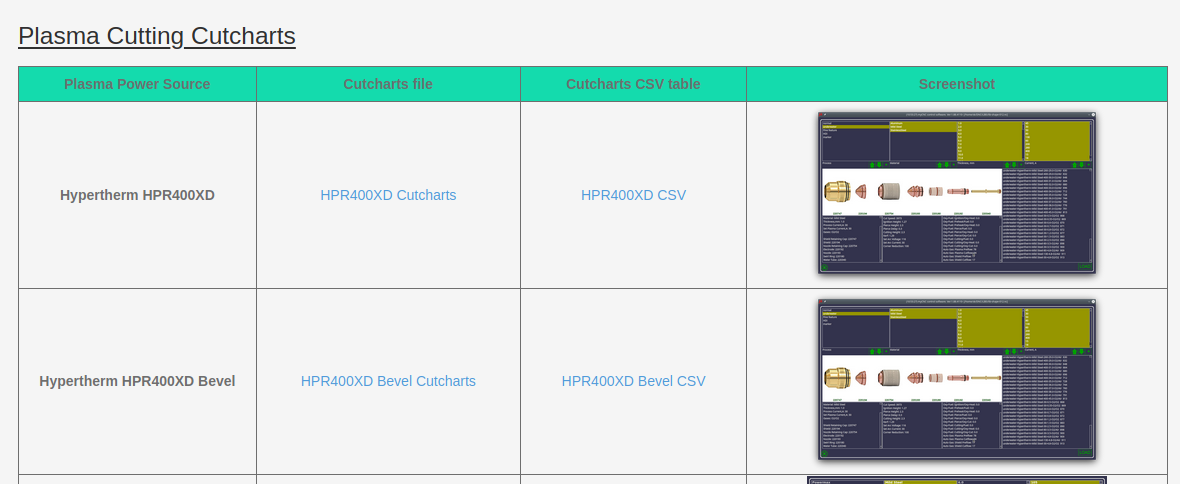

A new set of cutcharts is available for HPR400XD power sources (normal and bevel cutting).

Cutting parameters such as your Cutting speed, Current, Arc voltage, Ignition Height, Pierce height, and others can be loaded from the Cutcharts depending on the plasma power source, material type, material thickness and gases used.

Such a cutchart database is stored in the myCNC software as an SQLite database file. The new set of HPR400XD SQLite cutcharts can be downloaded from our Downloads page: .

.

Read more about cutcharts here.

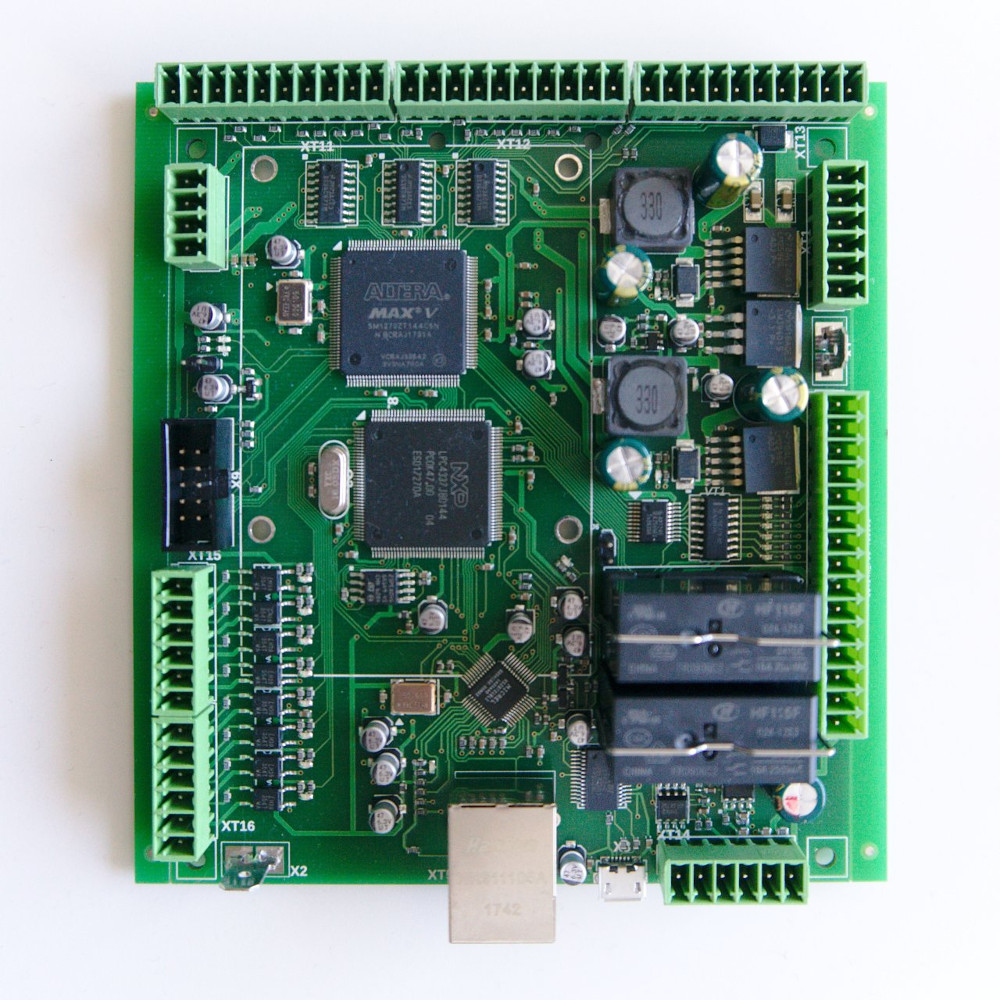

A new revision of the myCNC-ET6 (ET6R4C) controller board will be available soon to purchase through our online store. Notable changes include slight realignment of the component parts to prevent issues with input ports plug-in alignment as described here.

The new board versions will be available in the Shop in about two weeks from this blog post date. This new board version will be replacing the myCNC-ET6-R3C version currently available.

Stay tuned for more updates!

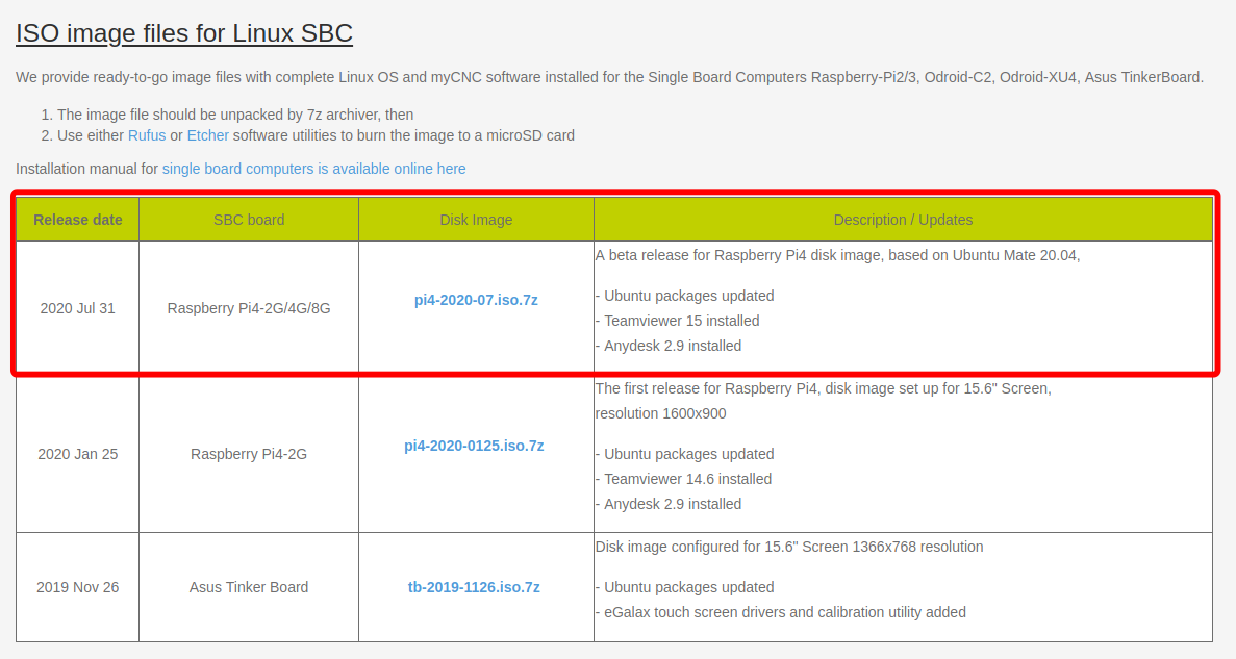

A new ISO image file for Raspberry Pi 4 is now available on our Downloads page. Raspberry Pi 4 computers with myCNC controllers provide a compact, easy-to-use CNC solution to clients looking to upgrade to a smaller, more affordable system.

The new version has been tested on the 2GB/4GB/8GB versions of the Raspberry Pi 4, and will be replacing the older Raspberry disk image, which was previously tested and configured only for the 2GB configuration.

For any issues noted with the new release, please reach out to us using the Contact Us page. Stay tuned for further updates!

We are happy to announce a new release of myCNC software, v1.88.4103.

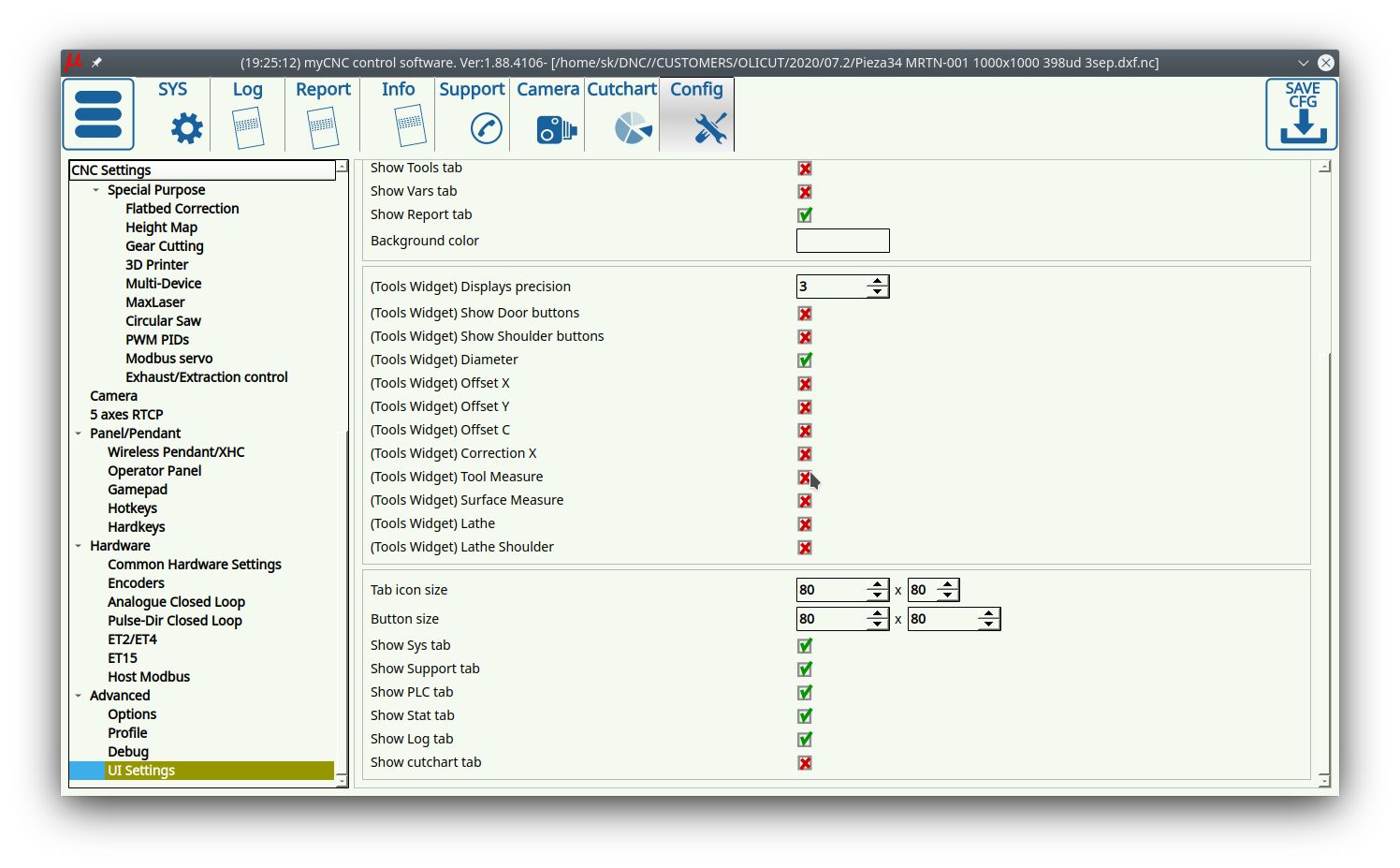

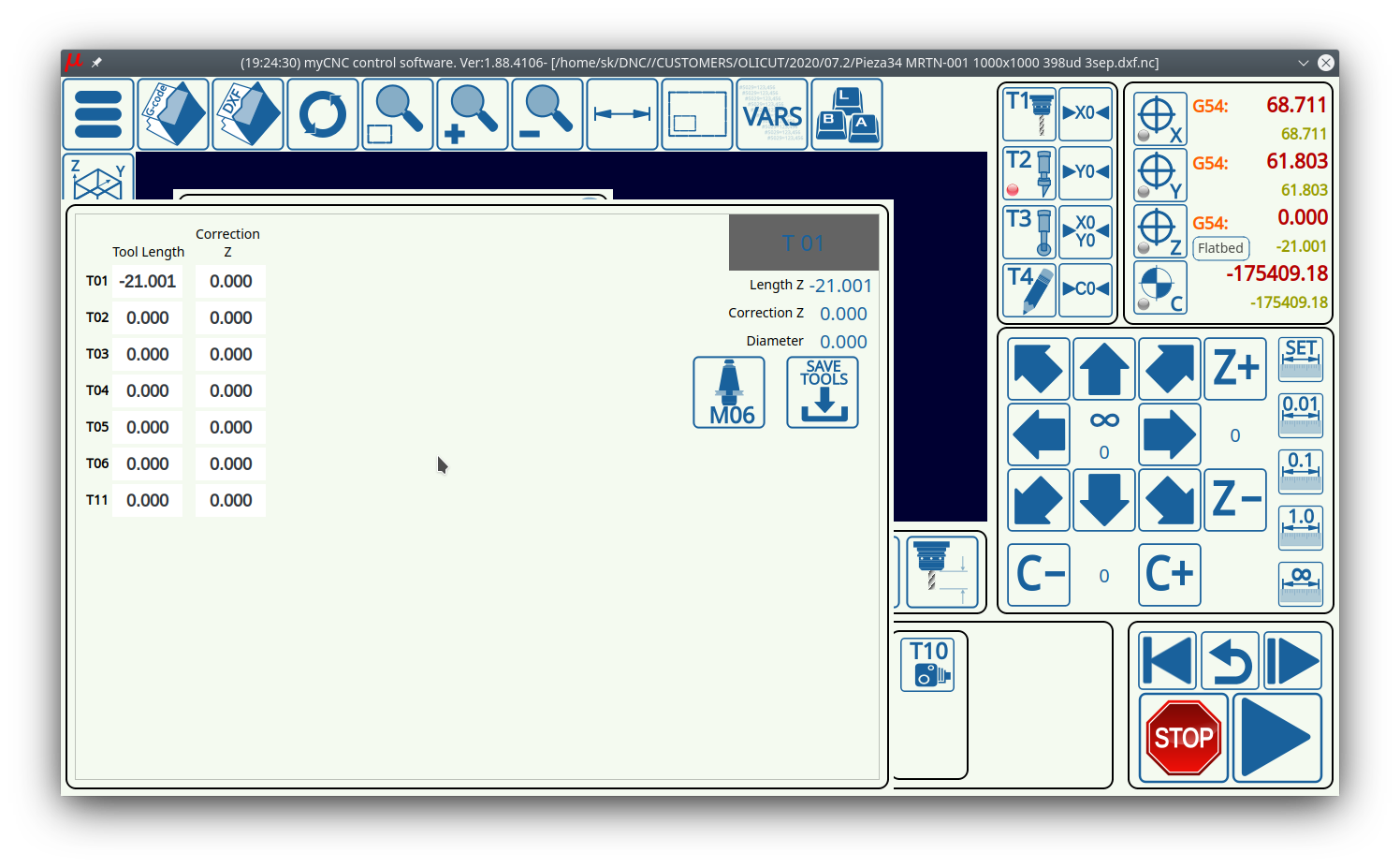

1. UI toggles for Tool Specifications window added in UI Settings

The user is now able to edit the appearance of the Tools window on the main myCNC screen from the UI Settings tab. The UI Settings tab allows you to select the necessary elements of the Tools window by setting the check marks next to the necessary UI options:

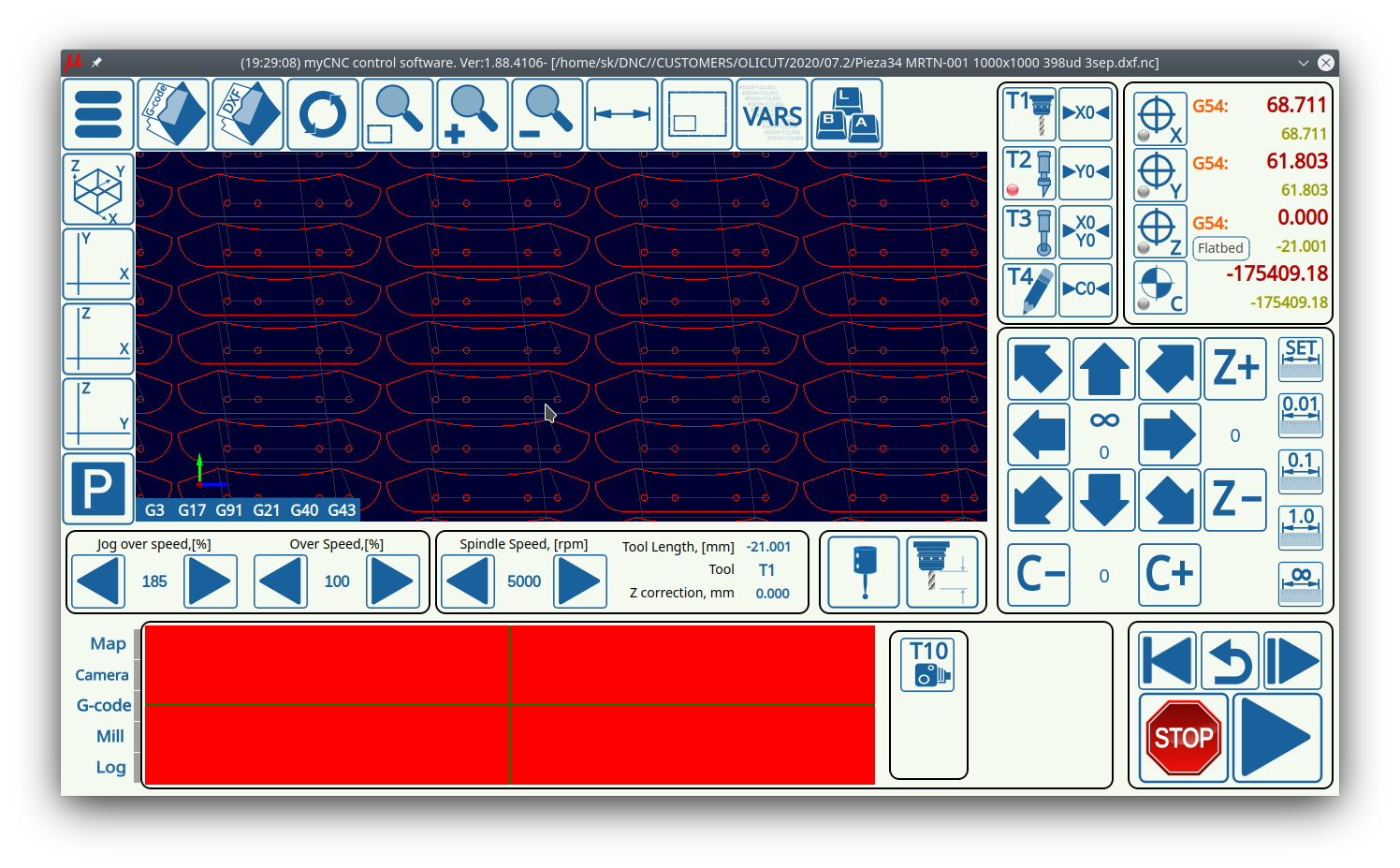

This is what the Tools window looks like with no UI elements selected.

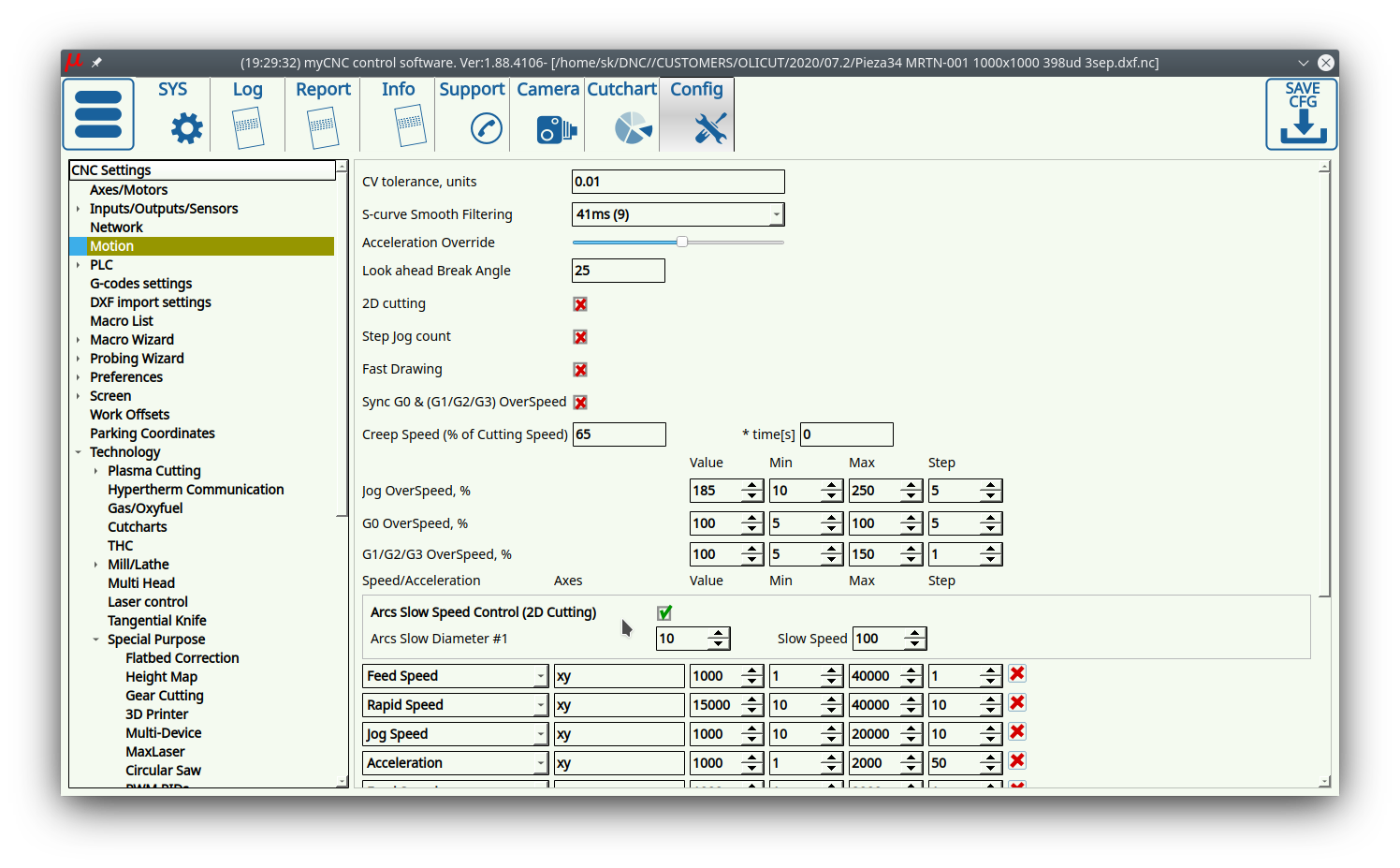

2. Coming soon: Hole Cutting options will be duplicated from Plasma Settings to Motion.

A 2D (or a 2.5D) file such as the one shown above contains both the outer and the inner contours of the part being cut. In certain applications, it is preferable to have a separate lower speed for the holes that are located inside the main contour.

The new settings in Settings > Config > Motion allow the user to toggle the Arc Slow Speed Control option, and is duplicated to this settings tab from the previous Technology > Plasma Settings tab. This is done in recognition of the fact that such an option is useful both for plasma and tangential cutting applications, and should thus be located in a general settings area.

Stay tuned for more updates!

A short demo video covering navigation in myCNC software, focusing on the plasma cutting X1366P profile.

Navigation in myCNC allows the user to quickly move around the program and to easily change the program start point via the "Bind start point" button.

The following three points are covered in the demo video:

1) "Bind start point" button and navigating in software G-code,

2) Next and Previous Part functionality (for example, for parts denoted by the M71 pierce commands), and

3) Running the program backwards.

For more information on myCNC functionality, please visit the Documentation Wiki.