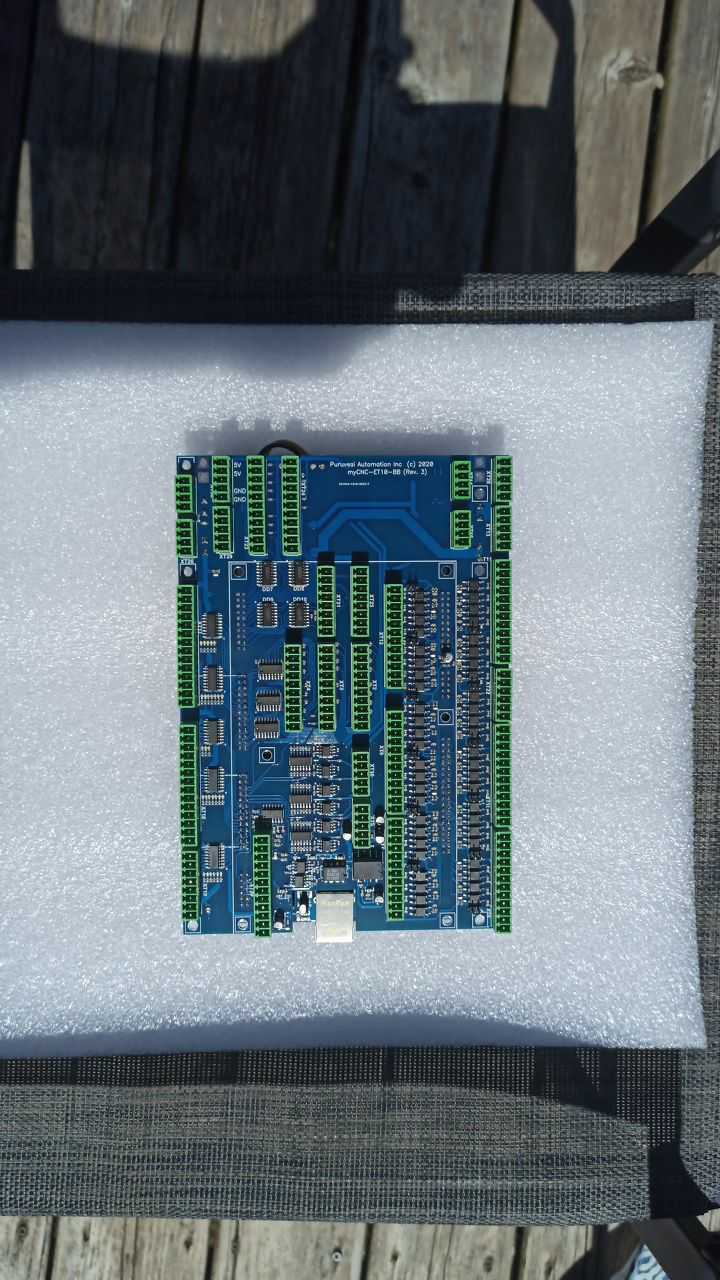

A new breakout board is now available for the ET10/ET15 controllers.

The breakout board features ADC galvanic isolation for usage in plasma cutting machines, and is compatible with both the ET10 and ET15 controllers (more info on the myCNC-ET15 coming soon).

The pricing for the ET10 controller with the new breakout board (model ET10R5C) will be $879, and will be purchasable though our Online Store in the coming days.

We have added pages for the videos and photos of our clients' machines and workshops on our website.

These pages can be found under Media Files > Videos > Client Videos, Media Files > Photos > Machine Photos, and Media Files > Photos > Manufactured Parts Photos.

A sneak peak at some of the content now being displayed there:

|

Gear cutting with a myCNC controller |

Height mapping in action |

|

Flycut laser engraving |

Plasma cutting with myCNC-ET7 |

|

Fume exhaust control for a plasma cutting table using myCNC |

Fadal 4020 ATC Mill retrofit |

Direct links to the new pages:

Stay tuned for more updates, and stay healthy!

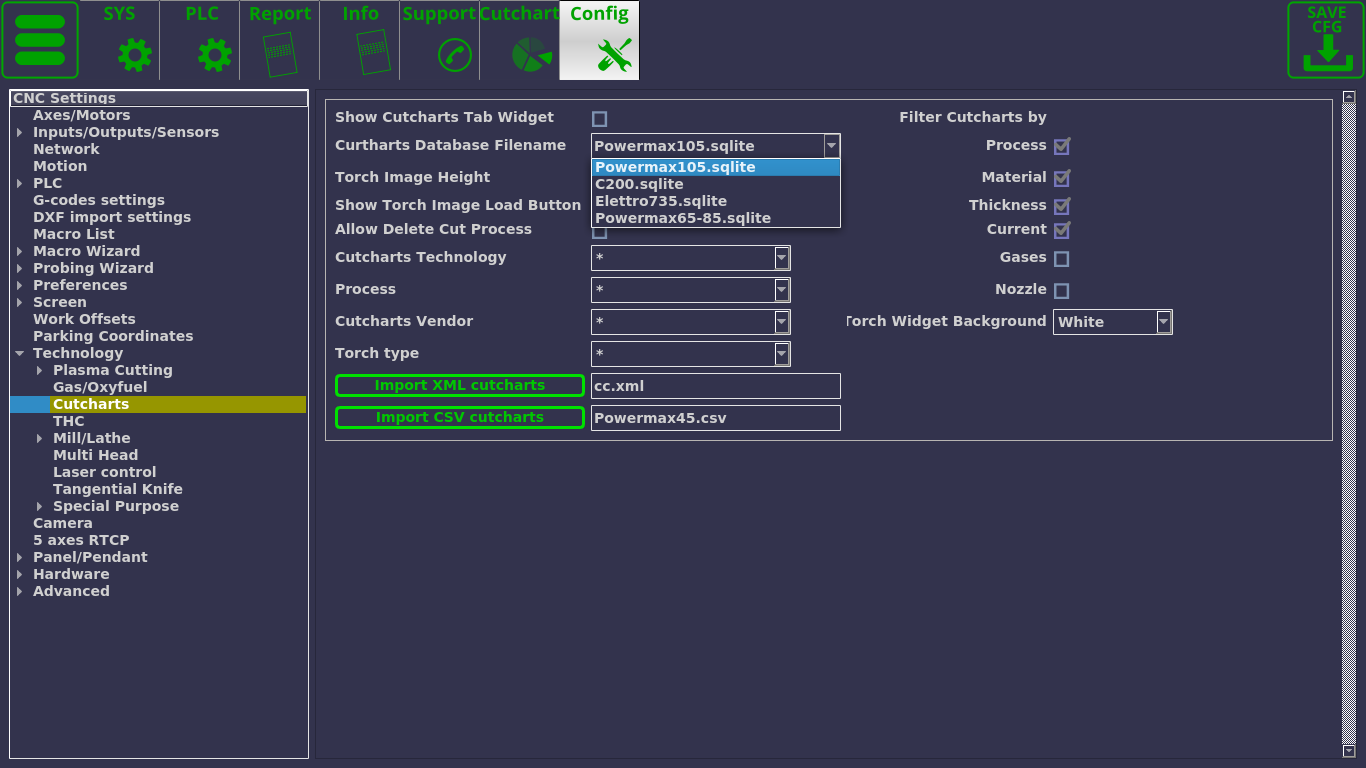

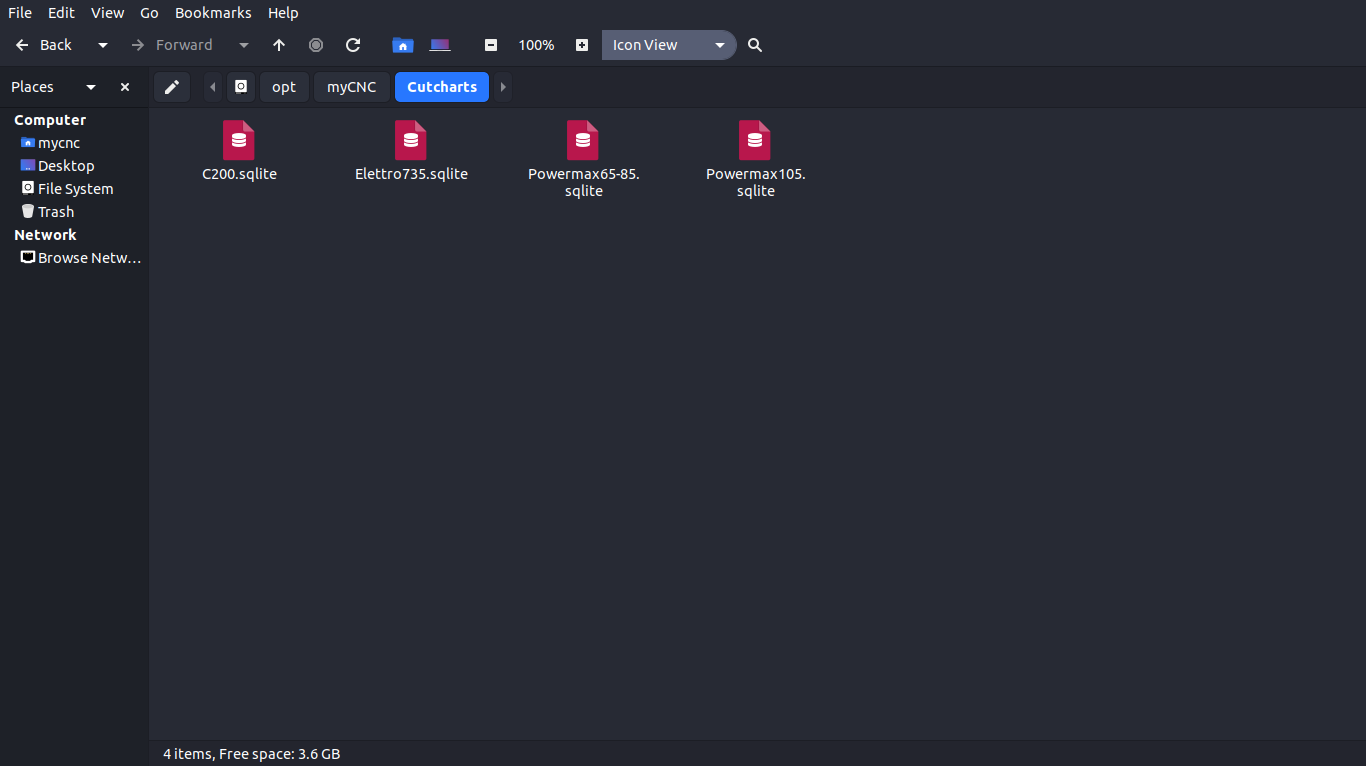

The latest release of myCNC software (version 1.88.3863) features improvements to cutcharts organization for X1366P/X1366G profiles, as well as bugfixes for individual cutcharts.

New cutcharts loading system

Previously, cutcharts were loaded into myCNC by having the user type in the full name of the cutcharts file. Now, if the file is located within the Cutcharts folder on your computer, a list of available files will be displayed when clicking on the Cutcharts Database Filename field:

Bug fixes

- Fixed incorrect images as well as incorrect consumables' numbers being displayed in some Powermax cutcharts

More information about cutcharts can be found on our website and in our documentation wiki.

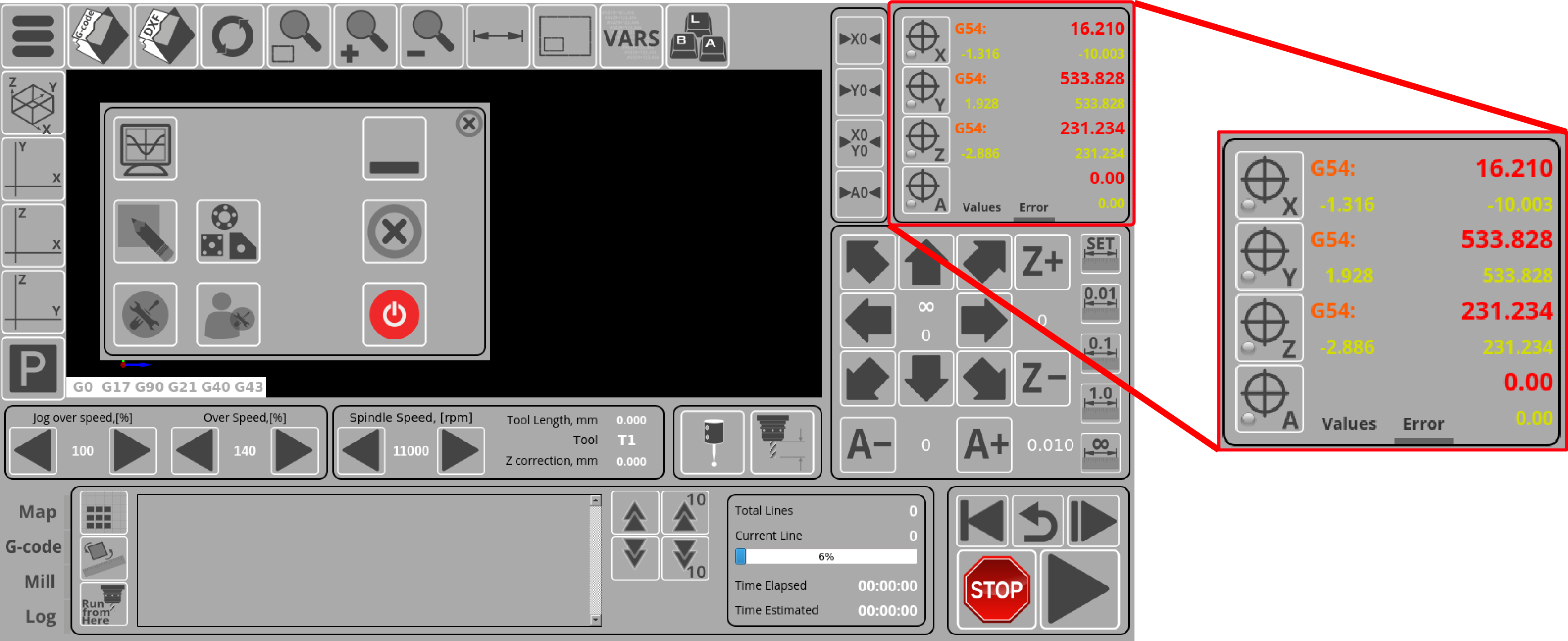

The new version of X1366M4E profiles features an easy way for the user to compare the current linear encoder value and the error between the expected and the real position of the machine. The coordinates tab has been reworked to feature a Values and Error sections, which display the encoder information.

The new version of this profile will be available on our Downloads page.

For more information about encoder setup, please visit our documentation wiki.

This video shows an ATC unit on a mill machine utilizing a myCNC-ET15 controller. This controller will have 8 motor inputs, 8 analog +-10V channels, 72 input ports and 72 output ports. At the moment, the controller is being tested with a full release expected later this year.

More information about the myCNC-ET15 motion controller is available on our Preview page in the Documentation Wiki.

Stay tuned for more information!