The myCNC team is currently working on starting up a machine for plasma cutting square tube sections.

The following video demonstrates the visualizations for tube plasma cutting that is utilized:

Note: The screen is currently under development and does not represent the final product, so some features may be missing.

Stay tuned for more updates!

The video above illustrates the testing cuts on a new dental CNC ATC mill from one of our clients. More videos from this series are available on our YouTube channel, and are added as the machine is being tested.

The machine is using a myCNC-ET7 motion controller. Find out more about the ET7 here.

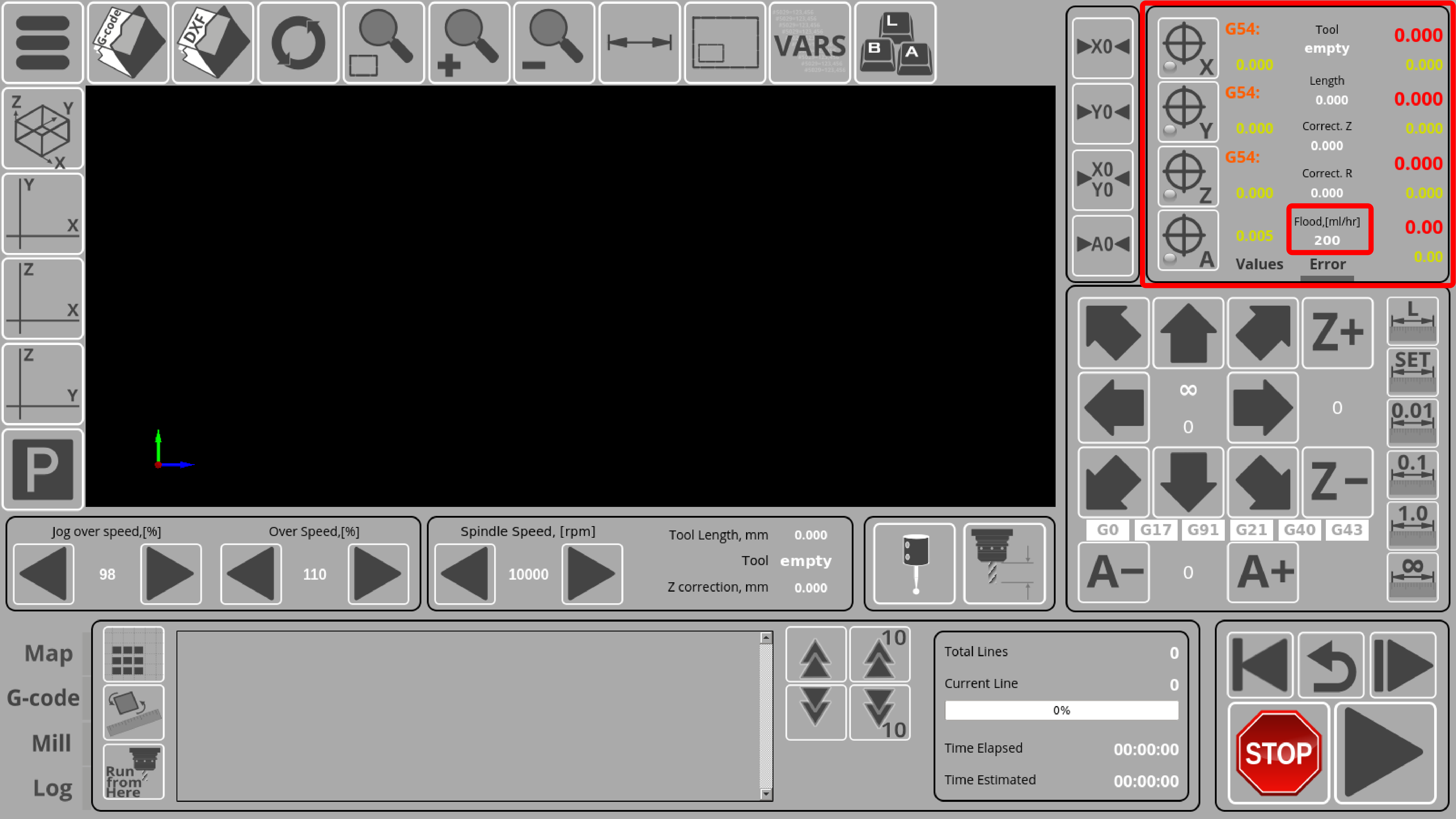

The new version of the X1366M4E (4-axis mill profile with encoder support) has some ease-of-use additions in regards to MQL (minimum quantity lubrication) and other information visibility.

The new version features an updated Coordinates section. with additional displays for tool specifications, tool diameter correctons, as well as a Flood display, which brings to the forefront the coolant flood rate for the MQL implementation in myCNC.

The profile can be downloaded from our Downloads page.

Stay tuned for more updates!

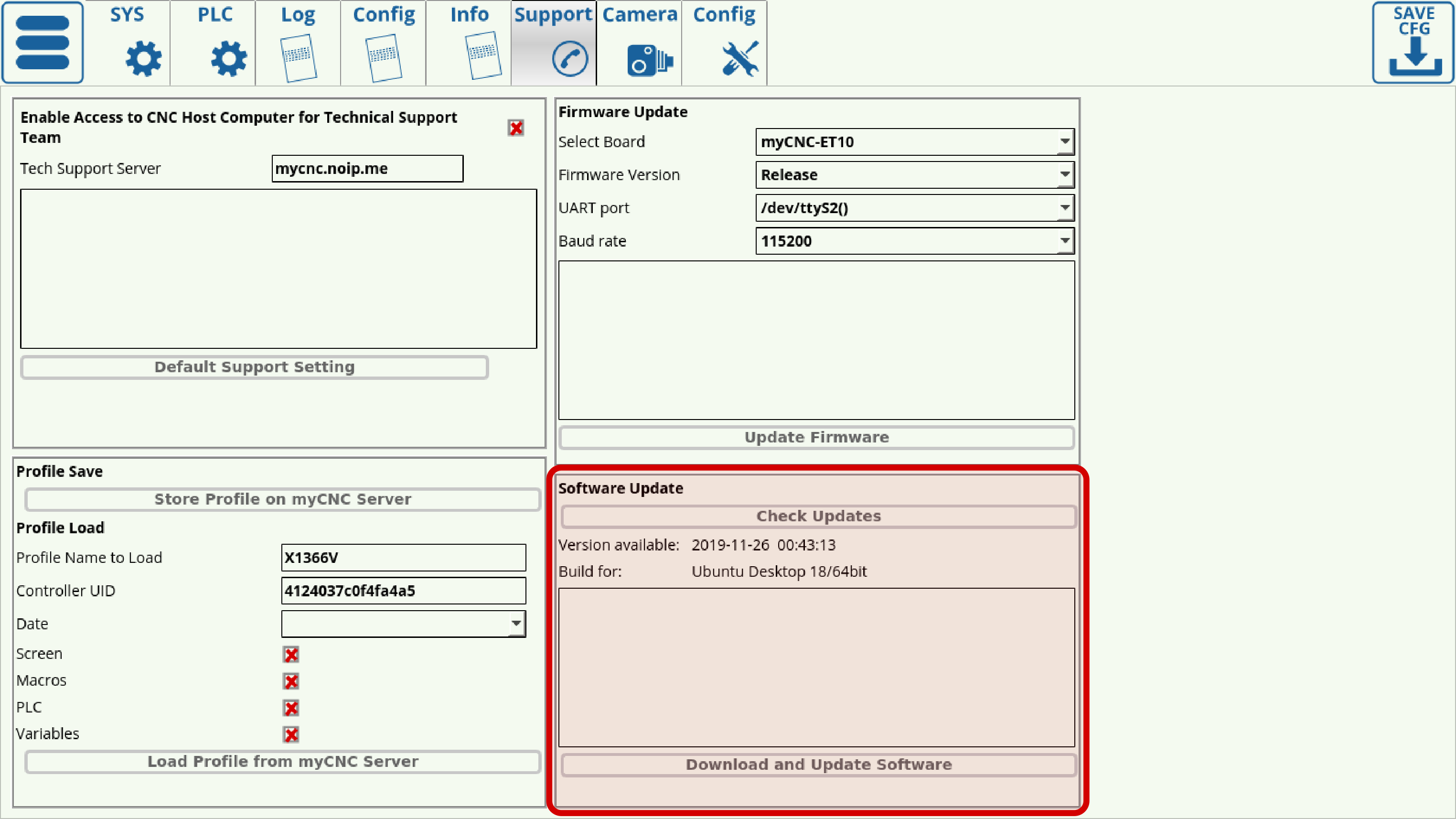

A new version of myCNC software (version 1.88.4151) has been released.

New features

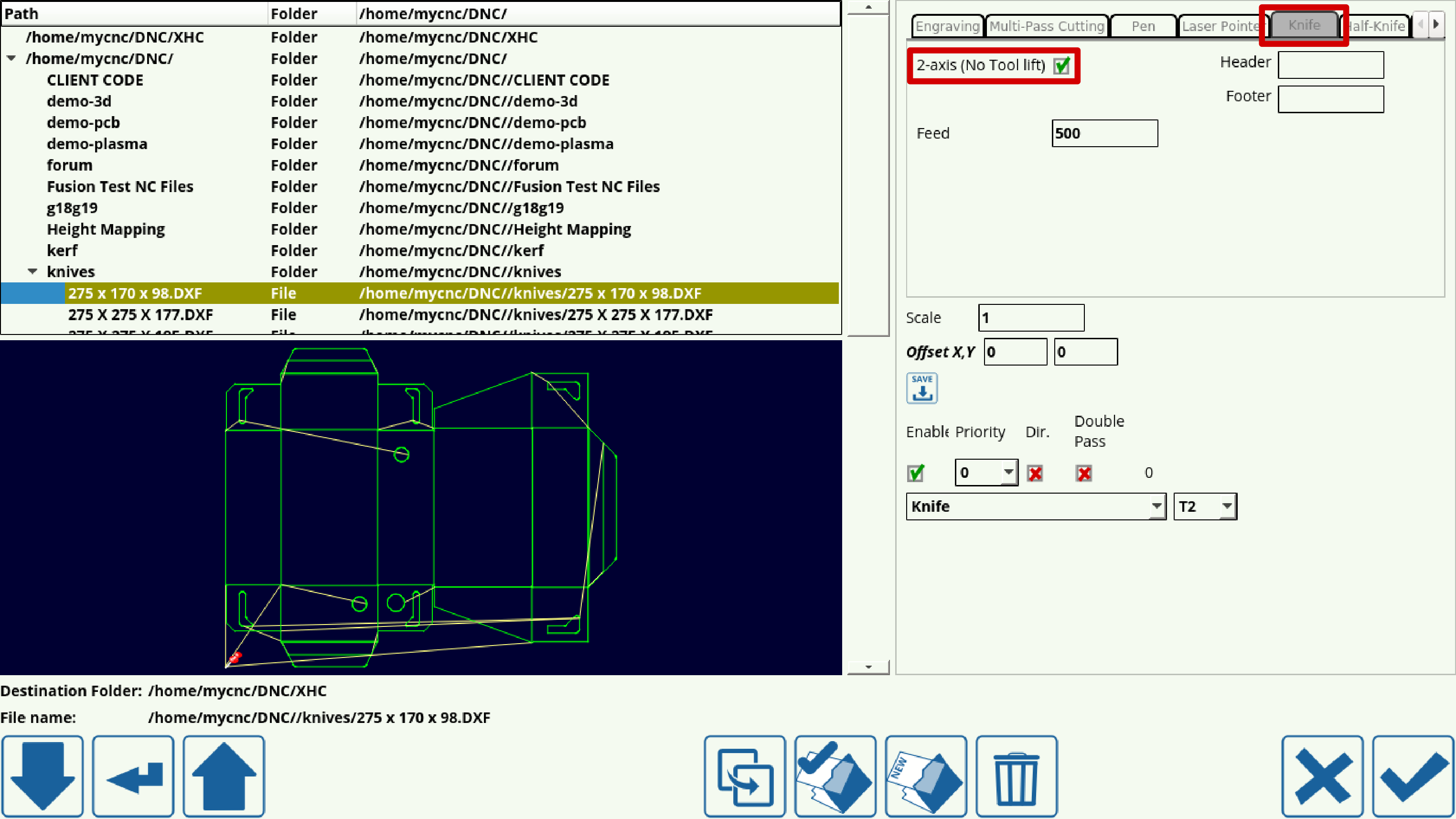

2-axis configurations support for Creasing Wheel and Pen setups when using the DXF import, in addition to the existing Knife and Half-Knife configurations:

Select the Knife check mark for the 2-axis configuration to be mirrored across to the Pen tool.

Bug fixes

Fixed an issue with the DXF import not correctly recognizing the 2-axis configurations at low turning angles (Z-axis motor movements were added despite 2-axis configuration being selected).

You can update through the Support tab in the myCNC settings:

Stay tuned for more updates!

Hello everyone!

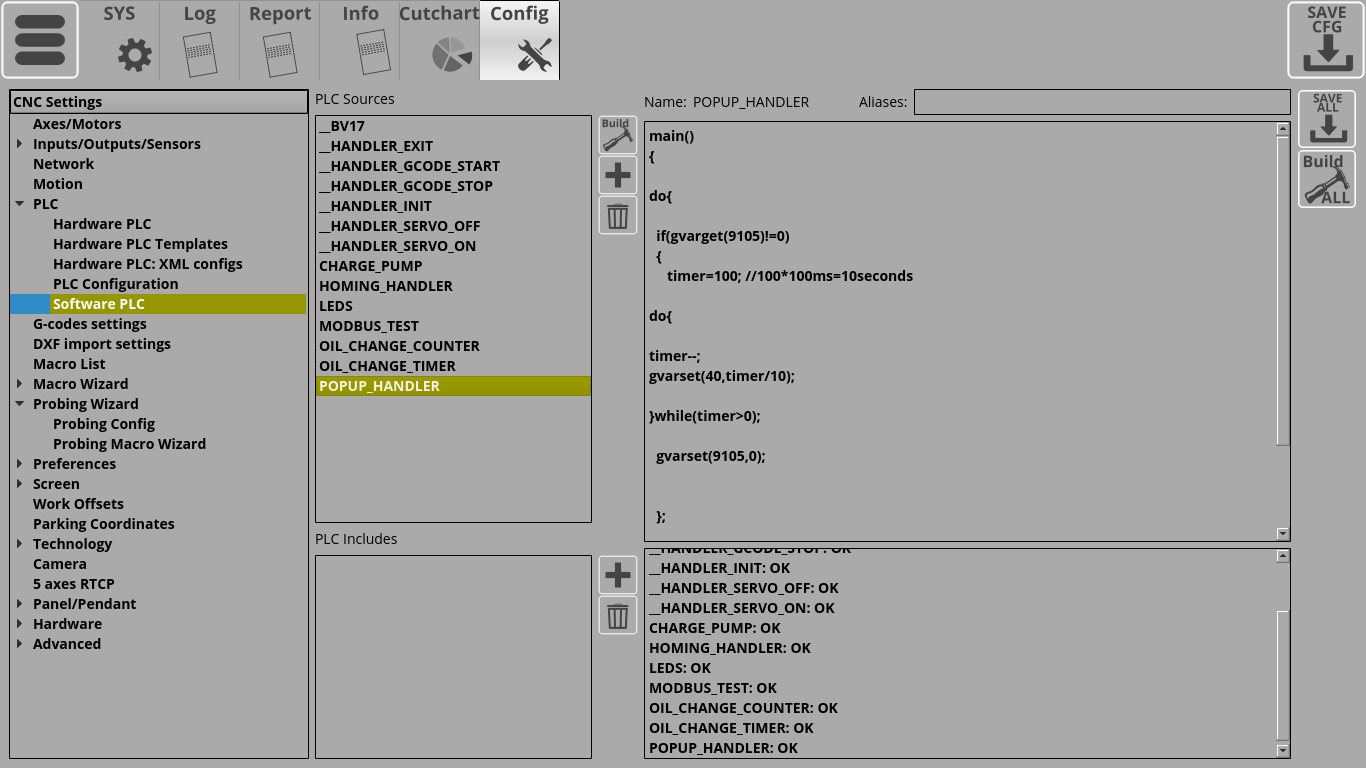

In the upcoming software release of myCNC, software PLC commands have been expanded, with some new capabilities added.

1. Ability to move your axes directly from software PLC by using the 100020-100027 variables.

Example to move 100 mm in the X-axis:

gvarset(100020, 100);

2. Ability to launch Hardware PLCs from your Software PLC commands. This is done via the 100041 and 100040 commands.

Example to launch Hardware PLC M607 with the eparam 333:

gvarset(100041, 333);

gvarset(100040, 607);

Read more about our Software PLC here.